6.6 Duramax LB7 Injector Replacement: Costs, Process & What to Expect

22 February 2026

How Common Rail Diesel Injectors Are Tested: Inside Our Bosch-Certified Test Bench

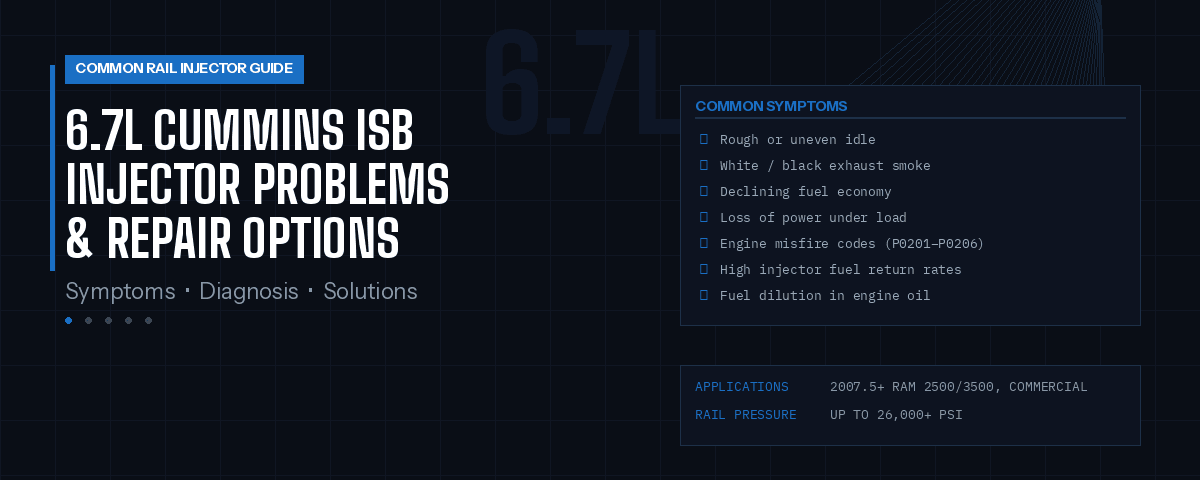

22 February 2026The 6.7L Cummins ISB turbodiesel — found in 2007.5 and newer Dodge/Ram 2500 through 5500 trucks and a wide range of commercial and industrial applications — is one of the most capable and widely used medium-duty diesel engines on the market. It delivers strong power, good torque characteristics, and when properly maintained, excellent longevity.

But the 6.7’s common rail fuel injection system operates at pressures exceeding 26,000 PSI in some applications, and the injectors are precision components that don’t tolerate neglect. When they start to fail, the symptoms can range from subtle drivability issues to expensive cascading damage.

At Valley Fuel Injection & Turbo, we’re a Bosch-certified diesel center that specializes in common rail system diagnosis and repair. We carry remanufactured 6.7 Cummins injectors rebuilt to OEM specifications with updated Bosch internals. This guide covers everything you need to know about 6.7 Cummins injector problems.

Understanding the 6.7 Cummins Fuel System

Before diving into failure modes, it helps to understand what you’re working with. The 6.7 Cummins uses a Bosch common rail fuel injection system consisting of three primary components:

High-Pressure Fuel Pump: The 2007.5–2018 trucks use a Bosch CP3.3 high-pressure pump, which is generally considered very reliable. Some later applications (particularly certain cab & chassis and commercial variants) use the CP4.2 pump, which has a more mixed reliability reputation. For a deep dive on CP4 issues, see our article on CP4 Injection Pump Failures.Common Rail: A high-pressure fuel rail that stores pressurized fuel and distributes it evenly to all six injectors. Operating pressure is controlled by the ECM and can range from approximately 5,000 PSI at idle to over 26,000 PSI under full load.Fuel Injectors: Six Bosch solenoid-actuated common rail injectors (one per cylinder) that receive high-pressure fuel from the rail and deliver precisely metered fuel into each combustion chamber. The ECM controls injection timing, duration, and can command multiple injection events per combustion cycle (pilot, main, and post injections).The 6.7 has gone through several injector iterations across model years, and not all injectors are interchangeable. The primary generations are:

Always verify the exact OEM part number for your application before ordering replacement injectors. Bosch part numbers, Cummins part numbers, and vehicle application can all vary.

Common Symptoms of 6.7 Cummins Injector Failure

Injector problems on the 6.7 tend to develop gradually, giving you time to diagnose and address them before they cause secondary damage — if you know what to watch for.

Rough or Uneven Idle

A healthy 6.7 Cummins idles smoothly. If the engine develops a noticeable shake, lope, or unevenness at idle — particularly when cold — one or more injectors may not be delivering fuel evenly. This is often the earliest noticeable symptom.

Excessive Exhaust Smoke

The type of smoke matters:

- White smoke at cold start that clears after warmup: Often indicates incomplete combustion from poor injector atomization. Can also be glow plug related, but if glow plugs check out, suspect injectors.

- Black smoke under load: Can indicate an injector that’s over-fueling due to a stuck-open nozzle or incorrect spray pattern.

- Consistent white/gray smoke at all temperatures: May indicate a cracked injector body or severe internal leak allowing fuel into the cylinder without proper atomization.

Increased Fuel Consumption

When injectors leak internally — fuel bypassing the nozzle and returning to the tank through the return circuit — the high-pressure pump has to work harder to maintain rail pressure. The ECM compensates by commanding more pump output, and overall system efficiency drops. If you’re tracking fuel economy and notice a sustained decline of 1–2 MPG or more with no other changes, injectors are a likely cause.

Loss of Power

Worn injectors that can’t deliver the commanded fuel quantity starve the engine under load. You’ll notice reduced pulling power, sluggish acceleration, and the engine may feel like it “hits a wall” at higher RPM. The ECM may also activate engine derating if it detects rail pressure that can’t keep up with demand.

Engine Misfires and Related Codes

Common 6.7 Cummins injector-related diagnostic codes include:

- P0201–P0206 — Injector circuit malfunction (cylinders 1–6)

- P0300 — Random/multiple cylinder misfire detected

- P0301–P0306 — Specific cylinder misfire

- P0087 — Fuel rail/system pressure too low

- P0088 — Fuel rail/system pressure too high

- P2146/P2149 — Injector group circuit issues

- P0093 — Fuel system leak detected (large)

High Fuel Return Rates

Similar to other common rail systems, measuring the fuel return volume from each injector is the definitive diagnostic method. Injectors that return significantly more fuel than specification have failed internal seals. This test requires proper measuring equipment and familiarity with the specific return rate specs for your model year.

Fuel in the Engine Oil

In severe cases, a cracked injector body or severely worn injector can allow fuel to leak into the cylinder and wash past the piston rings into the crankcase. If your oil level is rising between changes or the oil smells strongly of diesel, this is a serious condition that needs immediate attention — fuel dilution destroys bearing surfaces and accelerates engine wear.

What Causes 6.7 Cummins Injectors to Fail?

Fuel Contamination

Water, dirt, and microbial growth in diesel fuel are the enemies of common rail injectors. The 6.7’s injectors have internal clearances measured in microns — even tiny particles or water droplets can score surfaces, erode seats, and cause premature wear. The factory fuel filtration on the Ram trucks is good but not immune to being overwhelmed by a bad tank of fuel.

Ultra Low Sulfur Diesel (ULSD) Lubricity

Modern ULSD contains significantly less natural lubricity than the diesel fuel available when these engines were initially designed. The internal moving parts of common rail injectors rely on fuel as their lubricant. Reduced lubricity accelerates wear on needle valves, control valves, and internal seats. This is a factor across all modern diesel applications, not just Cummins.

DPF Regeneration Stress

The 6.7 Cummins uses Diesel Particulate Filter (DPF) regeneration to burn off accumulated soot. During regeneration, the ECM commands late post-injection events to send unburned fuel into the exhaust to raise exhaust temperatures. These additional injection cycles add stress to the injectors — they’re firing more frequently than they would in a pre-emissions engine. Frequent short-trip driving that triggers excessive regeneration cycles compounds this wear.

Age and Mileage

Even with perfect fuel quality and maintenance, common rail injectors are wear items. The solenoid valve, needle valve, and nozzle tip all experience billions of high-pressure cycles over the life of the engine. Most 6.7 Cummins injectors begin to show measurable wear somewhere in the 150,000–250,000 mile range, though actual life varies widely based on operating conditions.

Electrical Issues

The 6.7 Cummins injectors are controlled by the ECM via electrical solenoids. Wiring harness problems — chafed wires, corroded connectors, or poor grounds — can cause injectors to fire erratically, not fire at all, or fire at the wrong time. Always verify the electrical system before condemning the injectors themselves.

Diagnosing 6.7 Cummins Injector Problems

Step 1: Read and Record Diagnostic Codes

A quality scan tool (Cummins INSITE, Snap-on, or equivalent) will reveal injector-specific fault codes and, importantly, allow you to view live data including:

- Commanded vs. actual rail pressure

- Individual injector timing correction values

- Fuel temperature

- Injector-specific fault history

Step 2: Check Injector Fuel Return Rates

Using a calibrated return fuel measurement system, capture the volume of fuel returning from each injector at idle and at elevated RPM. Compare results to Cummins specifications for your model year. This is the single most reliable way to identify which injectors have failed.

Step 3: Perform a Cylinder Contribution Test

With a capable scan tool, the ECM can individually disable each injector to measure its contribution to engine output. A cylinder that shows no change when its injector is disabled was already contributing little — pointing to a dead or heavily degraded injector.

Step 4: Rule Out Other Causes

Before replacing injectors, verify:

- High-pressure pump output: Low rail pressure under load can mimic injector problems. Test CP3 (or CP4) output.

- Fuel supply pressure: Verify the transfer pump is delivering adequate low-pressure fuel to the CP3/CP4 inlet.

- Fuel filter condition: A restricted filter can cause pressure drop that mimics injector or pump issues.

- Wiring and connectors: Inspect the injector harness for damage, corrosion, or loose connections.

- Exhaust back pressure: A clogged DPF or failed EGR can cause symptoms that overlap with injector problems.

6.7 Cummins Injector Repair Options

Remanufactured Injectors (Best Value)

A remanufactured 6.7 Cummins injector is completely disassembled, cleaned, inspected, and rebuilt with new or reconditioned components to Bosch OEM specifications. This is the most cost-effective option for most truck owners and fleets.

At Valley Fuel Injection, our remanufactured Cummins injectors are:

- Rebuilt with updated Bosch components

- Flow-tested and spray-pattern verified

- Available for all 6.7 Cummins model year ranges

- Backed by a 12-month unlimited mileage warranty

- Available individually or as complete 6-injector sets

New Bosch Injectors

New units are available at a premium and make sense for fleet/commercial applications where maximum warranty coverage is needed.

Send-In Rebuild Service

If you want to keep your original injectors, you can ship them to us for professional testing and rebuild. We’ll test each injector on our Bosch-authorized equipment, provide a detailed report, and rebuild the serviceable units. Learn more about our diesel fuel injection services.

Should You Replace All Six or Just the Failed Ones?

On the 6.7 Cummins, replacing individual injectors is more practical than on the LB7 Duramax because access is easier (injectors are top-mounted with no valve cover removal). However, we still recommend replacing all six when possible for these reasons:

- Matched performance: A full set of remanufactured or new injectors delivers uniform fuel delivery across all cylinders, optimizing idle quality, power balance, and emissions.

- Cascade risk: If one injector has failed from wear, the remaining five have the same hours and are approaching the same point.

- Warranty simplicity: One purchase date, one warranty period for the complete set.

That said, if budget is a constraint and only one or two injectors have clearly failed on fuel return testing, replacing just the bad ones is a viable approach — especially on a truck with lower mileage where the remaining injectors still test within specification.

Preventing 6.7 Cummins Injector Failures

Fuel Filtration is Everything

The factory fuel filter should be replaced every 15,000 miles at minimum. If you operate in dusty environments, purchase fuel from rural or low-turnover stations, or tow frequently, consider shortening that interval to 10,000 miles. Always drain the water separator when the dash indicator illuminates — or on a regular schedule (monthly at minimum).

Use Quality Fuel Additives

A lubricity additive like Stanadyne Performance Formula, Opti-Lube XPD, or Hot Shot’s Secret Diesel Extreme added at each fill-up provides measurable protection to injector internals. This is one of the simplest and most cost-effective preventive measures available.

Monitor Your Fuel Economy

A sudden or gradual decline in fuel economy is often the first measurable indicator of injector wear. Track your MPG consistently — a sustained drop of 1+ MPG warrants investigation.

Don’t Ignore Regeneration Issues

If your truck is regenerating excessively (more frequently than every 200–300 miles in normal driving), there may be an underlying issue causing excess soot production — and those extra regeneration cycles are wearing your injectors faster. Diagnose and address the root cause.

Address Fuel System Contamination Immediately

If you suspect you received a bad tank of fuel (water, dirt, wrong fuel type), do NOT drive the truck until the contaminated fuel is drained and the system is flushed. Running contaminated fuel through 26,000 PSI injectors — even briefly — can cause immediate and permanent damage.

Frequently Asked Questions

How much does it cost to replace 6.7 Cummins injectors?

A single remanufactured 6.7 Cummins injector typically costs $250–$550 depending on model year, plus a core charge. A complete set of six remanufactured injectors runs $1,500–$3,300. Professional installation labor is typically $500–$1,200 for all six, as the 6.7’s top-mounted injectors are more accessible than some other platforms. Total cost for a full set installed usually falls in the $2,500–$4,500 range. Check our Cummins injector listings for current pricing.

How do I know if my 6.7 Cummins injectors are bad?

The most reliable method is a fuel return rate test performed with calibrated measuring equipment. Symptoms like rough idle, excessive smoke, reduced power, and declining fuel economy are strong indicators, but return rate testing identifies exactly which injectors have failed and how severely. Diagnostic trouble codes (P0201–P0206, P0300, P0087) provide additional confirmation. A qualified diesel shop can perform these tests in about an hour.

How long do 6.7 Cummins injectors last?

Under normal operating conditions with proper maintenance (regular fuel filter changes, clean fuel, lubricity additive use), 6.7 Cummins injectors typically last 150,000–250,000 miles. Some last longer, and some fail earlier depending on fuel quality, DPF regeneration frequency, and operating conditions. Fleet trucks that idle extensively or operate in dusty environments tend to see shorter injector life.

Can failing injectors damage my 6.7 Cummins engine?

Yes. A severely leaking injector can allow raw fuel to enter the cylinder and wash down the cylinder walls, diluting the oil and accelerating bearing and ring wear. If your oil level is rising between changes or smells strongly of diesel, address it immediately. Additionally, an injector with a poor spray pattern can cause localized hot spots on the piston, potentially leading to piston damage in extreme cases.

What’s the difference between the 2007-2012 and 2013-2018 6.7 Cummins injectors?

These are different injectors and are NOT interchangeable. The 2013+ injectors have a different electrical connector, updated nozzle design, and different flow characteristics. Always verify the correct Bosch part number and Cummins part number for your specific model year and application before ordering. If you’re unsure, contact our team and we’ll help you identify the correct injector for your truck.

Need Help With Your 6.7 Cummins Injectors?

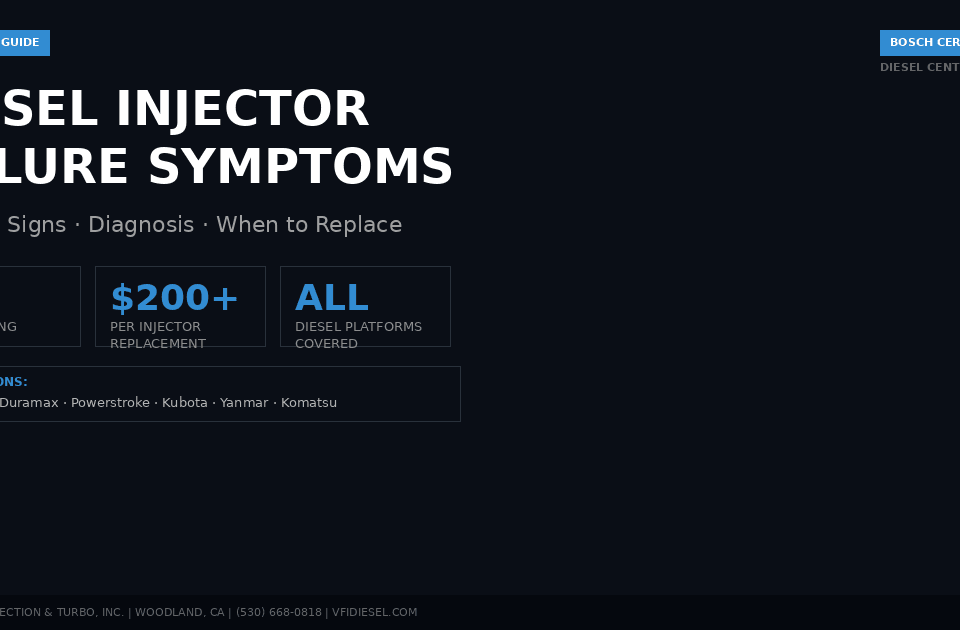

Whether you need remanufactured Cummins injectors shipped nationwide, professional injector testing and rebuild, or complete in-shop service at our Woodland, CA facility — Valley Fuel Injection is your resource.

We’re a Bosch-authorized diesel center with factory-certified technicians and the equipment to properly test, rebuild, and calibrate common rail injectors for all 6.7 Cummins applications — trucks, commercial, and industrial.

Call us: (530) 668-0818Email: info@vfidiesel.comVisit: 1243 E Beamer St, Suite C, Woodland, CA 95776Shop Cummins Injectors: vfidiesel.com/product-category/diesel-injectors/cummins/Valley Fuel Injection & Turbo, Inc. is an authorized dealer for Bosch, Kubota, Delphi, Yanmar, and Alliant Power. Located in Woodland, CA, we serve diesel owners and fleets throughout Northern California and nationwide via our mail-in repair and parts shipping services.