6.7 Cummins Injector Problems: Symptoms, Diagnosis & Repair Options

22 February 2026

Ford 6.0 Powerstroke Injector Problems: Why They Fail & How to Fix Them

22 February 2026When a diesel engine starts running rough, losing power, or blowing smoke, the injectors are usually the first suspects. But how do you actually know whether a common rail injector is good, marginal, or failed — without just guessing and swapping parts?

The answer is bench testing. And not the kind you can do in a garage with a multimeter. Real common rail injector testing requires specialized, calibrated equipment that can simulate the extreme pressures and electrical signals these injectors operate under — and measure their response with precision.

At Valley Fuel Injection & Turbo, we’ve invested in exactly that equipment. As a Bosch-certified diesel center, we test common rail injectors on professional-grade benches that replicate real-world operating conditions and measure performance against factory specifications.

In this post, we’ll walk you through exactly what happens when a set of injectors comes into our shop for testing — what we’re looking for, what the results mean, and how testing saves you money by identifying exactly which injectors need attention.

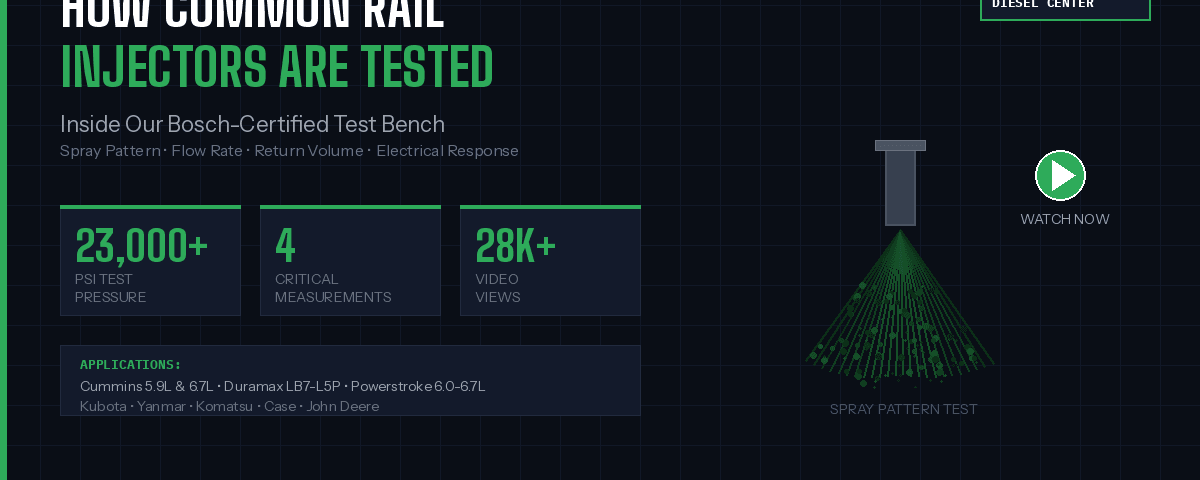

Watch: Common Rail Injector Testing at Valley Fuel Injection

Before we get into the technical details, watch our technicians testing common rail injectors on our bench. You’ll see the actual spray patterns, flow measurements, and testing process we use every day:

This video has been viewed over 28,000 times because diesel owners and technicians want to see what proper injector testing actually looks like. Most shops don’t have this equipment. We do — and it’s a core part of every injector diagnosis and rebuild we perform.

For a closer look at the equipment itself and how it handles different injector types, check out our follow-up video as well:

Why Bench Testing Matters: You Can’t Diagnose Injectors by Guessing

Common rail injectors operate at pressures exceeding 23,000–29,000 PSI depending on the application. They fire millions of times over their service life, with each injection event lasting just milliseconds. The internal components — needle valves, control valves, nozzle seats — wear in ways that are invisible to the naked eye and undetectable with basic tools.

Here’s the problem with skipping proper testing:

Symptom overlap. Rough idle, smoke, and power loss can be caused by injectors, but also by a failing high-pressure pump, restricted fuel filter, wiring issues, turbo problems, or a dozen other things. Replacing injectors based on symptoms alone means you might spend $2,000–$4,000 only to find the real problem was a $50 fuel filter or a $30 crank position sensor.Individual vs. set failure. In a set of six or eight injectors, usually only one or two have actually failed. Testing identifies exactly which ones need replacement — potentially saving you the cost of replacing the entire set if only a couple are out of specification.Quality verification. When we remanufacture injectors, every single unit is bench-tested before it goes back to the customer. This is how we guarantee that our remanufactured injectors meet OEM flow and spray pattern specifications. No testing = no guarantee.What We Test: The Four Critical Measurements

Professional injector testing evaluates four key performance areas. Each one tells us something different about the injector’s condition.

1. Spray Pattern

This is the most visually dramatic part of testing — and the one you can see in our video. Each injector has a precisely engineered nozzle that atomizes fuel into a specific cone-shaped spray pattern. A healthy injector produces a fine, uniform mist. A failing injector may:

- Stream instead of spray — fuel comes out in solid streams rather than atomized mist

- Produce an uneven pattern — spray is heavier on one side, indicating a partially blocked or eroded nozzle hole

- Drip after injection — fuel continues to leak from the nozzle after the injection event should have ended (this causes the “after-dribble” that leads to smoke and carbon buildup)

Spray pattern issues directly cause poor combustion, increased emissions, smoke, rough running, and reduced fuel efficiency.

2. Flow Rate (Delivery Volume)

We measure the exact volume of fuel each injector delivers per injection event at a given pressure and pulse width. This tells us whether the injector is delivering the correct amount of fuel — not too much (over-fueling, which causes black smoke and wasted fuel) and not too little (under-fueling, which causes power loss and misfires).

Flow rate testing is done at multiple operating points to simulate idle, cruising, and full-load conditions. The results are compared to Bosch’s published specifications for that specific injector part number.

3. Return Fuel Volume (Internal Leak-Down)

This is often the most revealing test. Every common rail injector has a fuel return line that carries excess fuel back to the tank. A healthy injector returns a predictable, small amount of fuel. When internal seals wear — particularly the control valve seat and needle valve seat — fuel bypasses the nozzle and goes straight to return.

Excessive return fuel means:

- The injector is wasting fuel (it’s being pressurized but not injected)

- The high-pressure pump has to work harder to maintain rail pressure

- Eventually, the pump can’t keep up and rail pressure drops, causing drivability problems across all cylinders

This is the same test that technicians perform on-vehicle as a diagnostic step, but bench testing gives us much more precise measurements under controlled conditions.

4. Electrical Response

The injector’s solenoid (or piezo actuator, on some applications) must respond to electrical commands with precise timing. We test:

- Solenoid resistance — must be within specification

- Response time — how quickly the injector opens and closes when commanded

- Consistent operation — the injector must fire identically every cycle, thousands of times in succession

An injector with sluggish electrical response will have delayed or inconsistent injection timing, even if the mechanical components are in good condition.

The Testing Process: What Happens When You Send Injectors to VFI

Step 1: Intake and Visual Inspection

When injectors arrive at our shop — whether hand-delivered or shipped to us from anywhere in the country — we log them in with your contact information and vehicle/engine details. We perform an initial visual inspection looking for obvious external damage, corrosion, cracked bodies, or damaged connectors.

Step 2: Cleaning

Before bench testing, injectors are cleaned to remove external carbon, dirt, and debris. This ensures the test results reflect the injector’s actual internal condition rather than surface contamination affecting the test.

Step 3: Bench Testing — Baseline Results

Each injector is mounted on our test bench and run through a complete test cycle at multiple operating points. We record spray pattern (visual and measured), delivery volume, return volume, and electrical response. These baseline numbers tell us exactly where each injector stands relative to specification.

Step 4: Diagnosis and Report

We compile the results into a clear report showing each injector’s performance. You’ll see exactly which injectors pass, which are marginal, and which have failed — and specifically what’s wrong with each one (excessive return, poor spray pattern, low flow, etc.).

Step 5: Recommendation

Based on the test results, we’ll recommend one of three paths:

- Pass — reinstall as-is. The injector meets all specifications and doesn’t need work.

- Remanufacture. The injector has serviceable wear that can be corrected by rebuilding with new internal components. After rebuild, it’s retested to verify it meets OEM specs.

- Replace. The injector body or a critical component is damaged beyond repair. We’ll recommend a new or remanufactured replacement from our inventory.

Which Injectors Can We Test?

Our bench equipment handles common rail injectors from all major manufacturers and platforms:

Truck Applications:- Cummins 5.9L & 6.7L ISB (2003+) — Shop Cummins injectors

- GM/Chevy 6.6L Duramax (LB7, LLY, LBZ, LMM, LML, L5P) — Shop Duramax injectors

- Ford 6.0L, 6.4L, 6.7L Powerstroke

- Ram/Dodge 5.9L & 6.7L Cummins

- Kubota common rail engines — Kubota service

- Yanmar diesel engines — Yanmar service

- Komatsu — Shop Komatsu injectors

- Case New Holland — Shop CNH injectors

- John Deere, Caterpillar, and other common rail platforms

Watch: The Hartridge Common Rail Injector Test Machine

Want to see the specialized equipment we use? This video shows our Hartridge common rail test bench in operation — one of the most advanced injector testing systems available:

The Hartridge system allows us to precisely replicate factory test conditions and measure injector performance to the same standards Bosch, Delphi, and Denso use during original manufacturing. This is the difference between a real test and someone just hooking up a pressure gauge and calling it “tested.”

Can You Test Injectors Yourself?

There are a few on-vehicle tests that can point you in the right direction:

Fuel return rate test: With basic measuring cups and fuel line disconnects, you can measure return fuel volume from each injector at idle. This is a good screening test but doesn’t tell you about spray pattern, flow accuracy, or electrical response.Scan tool diagnostics: A capable scan tool can show injector correction values, fuel rail pressure behavior, and misfire codes that indicate injector problems. This is useful for identifying which cylinders are affected.Resistance check: A multimeter can verify solenoid resistance is within spec. This catches dead or shorted coils but won’t detect mechanical wear.These tests are useful for initial diagnosis, but they can’t replace bench testing for definitive results. Bench testing is especially important before spending money on remanufactured or new injectors — you want to know for certain which ones need replacement.

Frequently Asked Questions

How much does it cost to have diesel injectors tested?

Injector testing at Valley Fuel Injection typically costs significantly less than the price of a single new injector. The exact cost depends on the injector type and how many you’re testing. The investment is worthwhile because it prevents unnecessary replacement of good injectors and identifies the specific units causing problems. Contact us for a quote on your specific application.

Can you test injectors that are still in the engine?

Some diagnostic tests (fuel return rate measurement, scan tool data analysis) can be performed with injectors installed. However, a complete bench test — including spray pattern verification, precision flow measurement, and full electrical testing — requires the injectors to be removed. For in-vehicle diagnosis, see our common rail system repair services.

How do I ship injectors to you for testing?

Package your injectors securely with protective caps on all fittings (to prevent contamination and damage), include your contact information and vehicle details, and ship to: Valley Fuel Injection & Turbo, Inc., 1243 E Beamer St, Suite C, Woodland, CA 95776. We’ll contact you with results and recommendations, typically within 2–3 business days of receiving your injectors. See our diesel fuel injection services page for more details on our mail-in service.

What’s the difference between your testing and a parts store “injector test”?

Most auto parts stores don’t test common rail injectors at all — their equipment handles gasoline port injectors. Common rail diesel injectors require specialized high-pressure test benches that can generate 23,000+ PSI and precisely measure delivery volumes in the milligram range. Our Bosch-certified equipment is the same caliber used by OEM manufacturers during production.

Can you test and rebuild my injectors on the same visit?

Yes. If you bring injectors to our Woodland, CA shop or ship them to us, we test first and then provide a recommendation. If rebuilding is viable, we can remanufacture them in-house and retest before returning them to you. The whole process — test, rebuild, retest — is handled under one roof with no need to send injectors to a third party.

Get Your Injectors Tested

Stop guessing. Whether you’re troubleshooting a drivability problem, verifying injectors before installation, or want to know exactly which ones in your set need replacement — professional bench testing gives you definitive answers.

Ship your injectors to us from anywhere in the country, or drive in to our Woodland, CA shop just 15 minutes north of Sacramento.Call us: (530) 668-0818Email: info@vfidiesel.comVisit: 1243 E Beamer St, Suite C, Woodland, CA 95776Services: vfidiesel.com/diesel-fuel-injection-services/Valley Fuel Injection & Turbo, Inc. is an authorized dealer for Bosch, Kubota, Delphi, Yanmar, and Alliant Power. Located in Woodland, CA, we serve diesel owners and fleets throughout Northern California and nationwide via our mail-in repair and parts shipping services.