7 Diesel Injector Failure Symptoms: Warning Signs You Shouldn’t Ignore

22 February 2026

Diesel Turbocharger Failure: 8 Warning Signs & What to Do

22 February 2026Published by Valley Fuel Injection & Turbo, Inc. | Woodland, CA

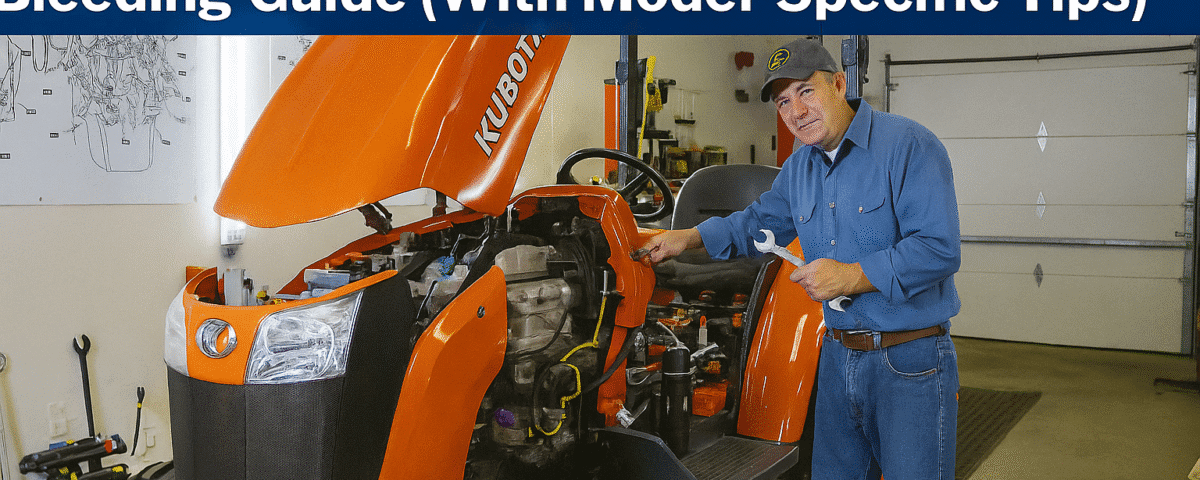

Authorized Kubota Engine Dealer & Bosch-Certified Diesel Specialists

Air trapped in the fuel system is one of the most common reasons a Kubota diesel cranks but won’t start — especially after running out of fuel, changing filters, or sitting idle for weeks or months between jobs. The engine sounds healthy, the starter cranks fine, but there’s no combustion because air is blocking fuel from reaching the injectors.

The fix is straightforward: bleed the fuel system to remove trapped air and restore fuel flow. It takes 5–15 minutes, requires basic hand tools, and saves you a $150+ service call every time.

This step-by-step guide covers the bleeding process for all Kubota diesel models — BX, B, L, M, and MX series tractors, KX and U-series excavators, SVL track loaders, RTV utility vehicles, and Kubota-powered generators and industrial equipment. At Valley Fuel Injection & Turbo, we’re an authorized Kubota engine dealer — we’ve bled thousands of Kubota fuel systems and stock the filters, primer parts, and injectors you’ll need if the problem goes deeper than trapped air.

Why Air in the Fuel System Prevents Starting

Kubota diesel engines — whether they use older mechanical injection or modern common rail systems — depend on a completely sealed, air-free fuel path from the tank to the injectors. Here’s why air causes problems:

- Diesel fuel systems are self-priming but not self-bleeding. The lift pump can push fuel through the system, but it can’t compress air out of the way. Air pockets sit in high points of the fuel lines and filter housing, blocking fuel flow.

- The injection pump needs liquid fuel to build pressure. On mechanical systems, the injection pump can’t pressurize air. On common rail systems, the high-pressure pump can’t build rail pressure without continuous liquid fuel supply — even a small air bubble drops rail pressure below the threshold needed to fire injectors.

- Air doesn’t combust like diesel. Even if some fuel gets past the air pocket, the air-fuel mix entering the cylinders won’t ignite properly. You get cranking with no firing, or brief sputtering that immediately dies.

When You Need to Bleed a Kubota Fuel System

Bleed the fuel system any time air could have entered:

- After running out of fuel — the single most common cause. When the tank runs dry, air fills every fuel line from the tank to the injectors.

- After changing fuel filters — removing a filter introduces air into the housing. Always bleed after filter changes.

- After the machine has been sitting for weeks or months — fuel can drain back to the tank through weakened check valves or deteriorated line connections, allowing air to fill the system

- After any fuel line disconnection — injector line service, pump removal, fuel tank repair, or any work that opens the fuel circuit

- After draining the water separator — opening the separator drain introduces air into the filter housing

Tools You’ll Need

- 10mm and 12mm wrenches (for bleeder screws and injector line nuts)

- Clean rags or shop towels — you’ll need several; this gets messy

- Container for catching fuel — a small pan or cut-off bottle

- Fresh, clean diesel fuel — for pre-filling the new filter

- Replacement fuel filter — if you’re bleeding after a filter change, the new filter should already be installed. If you’re bleeding for any other reason, replace the filter while you’re in there anyway. It’s the cheapest maintenance you can do.

- Safety glasses — diesel will spray when cracking injector lines

Step-by-Step: How to Bleed a Kubota Diesel Fuel System

This process works for virtually all Kubota diesel models. Model-specific notes are in the table below.

Step 1: Verify Fuel Supply

Confirm the tank has at least ¼ tank of clean, fresh diesel. If the machine ran dry, fill it now. Visually inspect all fuel lines from the tank to the engine — look for cracked rubber lines, loose fittings, or damaged connections. Any leak on the suction side (between tank and lift pump) will continuously draw air into the system even after bleeding.

Step 2: Locate the Fuel Filter Assembly and Primer

Find the fuel filter housing on your engine. On most Kubota engines, it’s mounted on the left side of the block. Identify three key components:

- Fuel filter — spin-on canister (most models) or cartridge-style

- Hand primer pump — a black rubber bulb or plunger mounted on or near the filter head. This is your primary bleeding tool.

- Bleeder screw — a small brass or steel screw on the filter head, usually 10mm. When loosened, it allows air to escape as you pump fuel through.

Step 3: Replace the Fuel Filter (If Due)

If you’re bleeding because of a filter change, the new filter should already be installed. If not, consider replacing it now — you’re already in the system, and bleeding a fresh filter prevents doing this twice.

- Place rags under the filter housing to catch spills

- Unscrew the old filter (counter-clockwise)

- Pre-fill the new filter with clean diesel before installing. This dramatically reduces the amount of air in the system and cuts bleeding time in half.

- Apply a thin film of clean diesel to the new filter’s rubber gasket

- Thread the filter on hand-tight, then tighten an additional ¾ turn. Do not use a wrench — over-tightening crushes the gasket and causes leaks.

Step 4: Bleed at the Filter Housing

This is the core of the process:

- Loosen the bleeder screw on the filter head 1–2 full turns

- Pump the hand primer — 50 to 100 strokes. You’ll feel increasing resistance as fuel fills the system and air is displaced.

- Watch the bleeder screw — you’ll see air bubbles in the fuel initially, then foamy fuel, then solid, bubble-free fuel. That’s your target.

- Once you see solid fuel flowing with no bubbles, tighten the bleeder screw snugly while continuing to hold pressure on the primer. This prevents air from being sucked back in as you tighten.

- Pump the primer another 20–30 strokes after tightening. The primer should now feel firm and stay firm — that means the system has fuel pressure.

Step 5: Attempt to Start

Turn the key and crank for no more than 10 seconds at a time. If the engine fires and runs, let it idle for 2–3 minutes, then gently rev to 1,500 RPM to purge any remaining air pockets downstream. If it sputters and dies, or doesn’t fire at all, move to Step 6.

Important: Don’t crank continuously for 30+ seconds. You’ll overheat the starter motor and drain the battery. Crank 10 seconds, rest 30 seconds, repeat.

Step 6: Crack Injector Lines (For Stubborn Air Locks)

If bleeding at the filter housing wasn’t enough — or if your model doesn’t have a primer pump (some older Kubota engines like the B7100) — you’ll need to bleed at the injector lines. This forces air out of the final section of the fuel system between the injection pump and injectors.

- Loosen 2 or 3 injector line nuts at the injectors (where the high-pressure lines connect to the injector bodies) — usually a 17mm flare nut wrench. Loosen just enough for fuel to seep past. Do not remove the lines.

- Crank the engine in 10-second bursts. Watch for fuel to appear at the loosened fittings — first bubbly, then solid.

- Tighten each fitting as soon as you see solid, air-free fuel at that injector

- Once all cracked fittings are tight, crank again — the engine should fire

- Wipe all spilled fuel immediately. Diesel on a hot exhaust manifold is a fire hazard.

Step 7: Confirm Normal Operation

Once the engine starts and runs:

- Let it idle for 2–3 minutes to stabilize

- Rev gently to 1,500–2,000 RPM several times to push remaining air through the return lines

- Watch for smooth, even idle with no sputtering or surging

- Check around the filter housing, bleeder screw, and injector line fittings for any fuel leaks. Tighten anything that’s weeping.

- If the engine runs rough for a minute then smooths out, that’s normal — the last traces of air are clearing

Model-Specific Bleeding Tips

| Kubota Model Series | Filter Location & Bleeding Notes |

|---|---|

| BX Series (BX1880, BX2380, BX2680, BX23S) | Spin-on filter under right step/footrest area. Primer pump on filter head. Bleeder screw faces toward the rear of the machine. Tight access — a short 10mm wrench helps. These D902 engines bleed quickly, typically 50 primer strokes. |

| B Series (B2301, B2601, B2650, B3350) | Spin-on filter near the battery on the right side. Primer pump requires firm, full strokes — 75+ pumps after a filter change is normal on these. D1105/D1305 engines. Allow extra cranking time on cold mornings after bleeding. |

| L Series (L2501, L3301, L3901, L4701) | Dual filter setup — primary (with water separator) and secondary/main. Bleed the primary filter first, then the secondary. If you only bleed one, air trapped in the other will prevent starting. V2403/V3307 engines on newer models. |

| M Series (M5, M6, M7) | Common rail injection system — higher pressure makes bleeding more critical. Bleed at the filter head first. If the engine still won’t start, the high-pressure pump may need bleeding at its inlet fitting. A scan tool to monitor live rail pressure while cranking confirms whether fuel is reaching the pump. V3307-CR/V3800 engines. |

| MX Series (MX5400, MX6000) | Similar to L series with dual filtration. V2403 engine. Filter access from the left side of the engine. Standard primer bleeding procedure works well. |

| KX/U Excavators (KX040, KX057, U35, U55) | Filter in the engine compartment — access varies by model but generally straightforward with panels removed. Electric lift pump primes for ~3 seconds when key is turned to ON. If you don’t hear the pump hum, check the pump relay/fuse before bleeding — a dead lift pump won’t self-prime regardless of bleeding. |

| SVL Track Loaders (SVL65, SVL75, SVL95) | Filter under the cab or rear service panel. V3307-CR engine on SVL75/95. Same common rail bleeding notes as M series — bleed filter first, then high-pressure side if needed. |

| RTV Utility Vehicles (RTV-X900, RTV-X1100, RTV-X1140) | Filter accessible from engine compartment. D902/D1105 engines. Straightforward mechanical injection — standard primer bleeding usually sufficient. |

| Generators / Industrial | Engine model varies (D902, D1105, V1505, V2203, V2403, etc.). Locate the filter and primer on the engine itself — the generator housing is just a shell around a standard Kubota engine. Same bleeding procedure as the corresponding engine model above. |

Bleeding Didn’t Work? What to Check Next

If you’ve bled the system thoroughly and the engine still won’t start (or starts briefly then dies), the problem is beyond trapped air. Here’s what to check in order of likelihood:

- Air leak on the suction side. If air keeps re-entering the system after bleeding, there’s a leak between the fuel tank and the lift pump. Check rubber fuel lines for cracks (especially where they connect to metal fittings), primer pump seals, filter housing O-rings, and the water separator drain valve. A suction-side leak won’t drip fuel — it sucks air in, making it hard to find visually. Use a clear hose on the return line to watch for bubbles while the engine runs.

- Failed lift pump. If the hand primer never gets firm, or the electric lift pump doesn’t hum when the key is turned ON, the pump can’t push fuel to the injection system. Test by checking fuel pressure at the injection pump inlet — it should read 3–8 PSI on most Kubota engines.

- Clogged fuel pickup or line. Debris in the tank, a collapsed pickup screen, or a kinked fuel line between the tank and filter restricts flow enough to prevent starting even with a bled system.

- Failed or worn injectors. If fuel is reaching the injectors but the engine won’t fire, the injectors themselves may be the problem — nozzles clogged with carbon, worn internally, or stuck. This is especially common on Tier 4 Kubota engines that have been running on contaminated fuel.

- Injection pump failure. Rare on Kubota engines but possible at very high hours. If fuel pressure at the pump inlet is good but nothing comes out the high-pressure side, the pump may need service.

- Glow plug failure. If the engine fires briefly then dies (especially in cold weather), the problem may be glow plugs rather than air — the fuel is getting there but can’t ignite in a cold cylinder. See our complete diesel no-start guide for glow plug diagnosis.

Common Bleeding Mistakes That Cause Repeat Problems

- Cranking for 30+ seconds continuously. This overheats the starter motor and drains the battery without effectively bleeding air. Use 10-second bursts with 30-second rest periods.

- Not pre-filling the new filter. Installing a dry filter means the primer has to push fuel through an empty canister AND the air that was in it. Pre-filling cuts bleeding time dramatically.

- Skipping the water separator drain. If you bleed the system but leave water sitting in the separator, that water will reach your injectors as soon as the engine runs. Drain it every time you’re in the fuel system. Water contamination is the #1 cause of Kubota injector failure.

- Reusing old fuel to fill the new filter. Fuel that came out of the old filter is full of the contaminants the filter caught. Use fresh, clean diesel from the can.

- Not finding the air entry source. Bleeding fixes the symptom — but if air entered because of a cracked line, failed check valve, or bad O-ring, it’ll happen again. Find and fix the cause.

When to Call a Professional

Bleeding is a basic maintenance skill that most equipment owners can handle. But if you’re dealing with repeated air locks, injectors that won’t fire even with fuel present, common rail pressure faults, or an engine that ran on contaminated fuel, the problem is deeper than air and requires professional diagnosis.

Valley Fuel Injection & Turbo is an authorized Kubota engine dealer and Bosch-certified diesel injection center in Woodland, CA. We specialize in exactly the problems that bleeding can’t fix:

- Kubota injector bench testing — determines which injectors are functioning and which need replacement

- Injector cleaning and recalibration — restores marginal injectors to OEM spec

- Injection pump diagnosis and repair

- Fuel system contamination cleanup — water, dirt, or algae in the system

- Mail-in injector testing — ship your injectors to us from anywhere, results in 1–2 business days

Kubota won’t start after bleeding? Need filters or injectors?

Call (530) 668-0818 or contact us online

We stock genuine Kubota filters, remanufactured injectors, and fuel system components. Same-day shipping on most in-stock parts.

Valley Fuel Injection & Turbo, Inc.

1243 E Beamer St, Suite C, Woodland, CA 95776

Monday–Friday, 7:00 AM – 4:30 PM PST

Related reading: Kubota Tier 4 Injector Problems · 7 Kubota Injector Maintenance Tips · Diesel Cranks But Won’t Start: 7 Causes · Diesel Injector Failure Symptoms · Diesel Engine Maintenance Services · Yanmar Engine Parts & Service