5.9 Cummins VP44 Injection Pump Failure: Complete Diagnosis & Repair Guide

16 February 2026

6.7 Cummins Injector Problems: Symptoms, Diagnosis & Repair Options

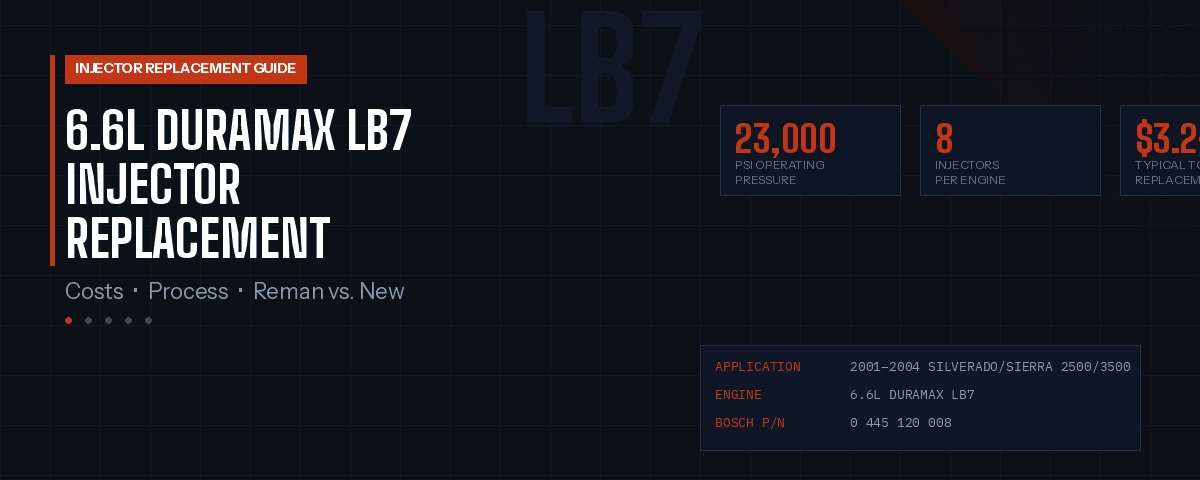

22 February 2026The 2001–2004 Chevrolet Silverado and GMC Sierra 2500HD/3500 with the 6.6L Duramax LB7 engine introduced GM into the modern diesel truck market — and it was a strong debut. The LB7 is known for solid power, good fuel economy, and a robust bottom end that can handle serious mileage.

But it has one well-documented Achilles’ heel: the fuel injectors.

LB7 injector failure is not a matter of if but when. GM acknowledged the issue with an extended warranty (Special Policy 04036) that covered injector replacement up to 200,000 miles — but that program has long since expired, leaving owners to handle replacement costs themselves.

At Valley Fuel Injection & Turbo, we’re a Bosch-certified diesel center and carry remanufactured Bosch LB7 injectors that are rebuilt to OEM specifications with updated internals. This guide walks you through everything you need to know before pulling the trigger on an LB7 injector replacement.

Why LB7 Injectors Fail

The LB7 uses Bosch common rail injectors (part number 0 445 120 008, among others) that operate at approximately 23,000 PSI. These are precision components with extremely tight internal tolerances, and several factors contribute to their eventual failure.

Internal Seal Degradation

The LB7 injector design has an internal ball seat that seals the high-pressure fuel circuit. Over time, this seat erodes from the constant cycling of high-pressure fuel, allowing fuel to bypass the seal and enter the return circuit. When this happens, fuel pressure to the nozzle drops, atomization suffers, and the injector no longer delivers fuel properly.

Nozzle Coking and Carbon Buildup

Combustion byproducts gradually build up on the injector nozzle tips, disrupting the spray pattern. Instead of a fine, atomized mist, the injector starts delivering fuel in streams or uneven patterns. This causes incomplete combustion, which generates more carbon — creating a self-reinforcing cycle of deterioration.

Fuel Quality Issues

Like all modern common rail systems, LB7 injectors are sensitive to fuel quality. Water contamination, particulate matter, and low-lubricity ULSD fuel all accelerate internal wear. For more on how fuel contamination destroys injection components, see our diesel fuel injection services page.

Electrical Harness Problems

The LB7’s injector wiring harness runs through the valve cover and is exposed to high heat and oil. Harness degradation can cause injectors to fire intermittently or not at all, sometimes mimicking injector failure. Always inspect the harness before condemning the injectors themselves.

Symptoms of Failing LB7 Injectors

LB7 injector problems produce distinctive symptoms. You may experience one or several of these simultaneously, and they tend to worsen progressively.

Rough Idle

This is typically the first noticeable symptom. The engine shakes or lopes irregularly at idle as one or more cylinders receive inconsistent fuel delivery. It’s often most noticeable when the engine is cold.

White or Blue-White Exhaust Smoke

Failed or failing injectors that aren’t atomizing fuel properly will produce visible smoke, especially at startup and idle. Unburned fuel passes into the exhaust as a white or bluish haze. Heavy white smoke at cold start that clears up after warmup often indicates one or more injectors with degraded spray patterns.

Increased Fuel Consumption

When injectors leak internally (fuel bypassing the nozzle seal and returning to the tank instead of being injected), the CP3 pump has to work harder to maintain rail pressure. More fuel is cycled through the system with less actually reaching the cylinders, reducing efficiency.

Reduced Power

As injector performance degrades, the engine loses power — particularly under load. Towing, pulling grades, or aggressive acceleration reveals the shortfall most clearly. The ECM may also derate the engine if it detects excessive fuel return rates.

Diagnostic Trouble Codes

Common LB7 injector-related codes include:

- P0201–P0208 — Injector circuit malfunction (cylinders 1–8)

- P0300 — Random/multiple cylinder misfire

- P0301–P0308 — Specific cylinder misfire

- P0087 — Fuel rail pressure too low

- P2146/P2149 — Injector group circuit open

Elevated Fuel Return Rates

This is the definitive diagnostic test. By measuring the volume of fuel returning from each injector to the fuel return system, a technician can identify exactly which injectors have failed internal seals. A healthy LB7 injector should return no more than approximately 40–60 mL per minute at idle. An injector returning 100+ mL/min is failed and needs replacement.

The LB7 Injector Replacement Process

Unlike later Duramax engines (LLY, LBZ, LMM) where injectors are accessed from the top of the engine, LB7 injectors are buried under the valve covers — making this a significantly more labor-intensive job.

What’s Involved

- Remove intake and turbo piping to access the valve covers

- Remove valve covers to expose the injectors and wiring harness

- Disconnect and remove injector wiring harness (inspect for damage)

- Remove high-pressure fuel lines from each injector

- Extract injectors using the proper puller tool (they’re sealed with copper crush washers and can be stuck)

- Clean injector bores thoroughly before installing new units

- Install new injectors with new copper crush washers, seals, and return line O-rings

- Reinstall wiring harness (replace if damaged — strongly recommended if original)

- Reinstall fuel lines, valve covers, intake components

- Prime fuel system, start engine, check for leaks, clear codes

Labor Time

The LB7 injector job typically takes 8–12 hours at a professional shop due to the valve cover removal and reassembly complexity. This is significantly more involved than an LLY or LBZ injector swap, which is why labor costs are higher on the LB7.

LB7 Injector Replacement Cost Breakdown

Here’s what you can expect to pay, broken down by component:

Parts

Labor

Professional shop labor for an LB7 injector job typically ranges from $1,200–$2,000 depending on the shop rate and whether additional work (glow plugs, harness, etc.) is done at the same time.

Total Estimated Cost

Remanufactured vs. New LB7 Injectors

This is one of the most common questions we get, and the answer is straightforward for most owners.

Remanufactured Bosch LB7 Injectors

A properly remanufactured LB7 injector is completely disassembled, inspected, fitted with new or reconditioned internal components (including updated nozzles, seals, and solenoids), and tested to OEM flow and spray pattern specifications on calibrated Bosch test equipment.

At Valley Fuel Injection, our remanufactured Duramax LB7 injectors are:

- Rebuilt with updated Bosch components

- Flow-tested and spray-pattern verified on Bosch-authorized equipment

- Backed by a 12-month unlimited mileage warranty

- Available with core exchange for reduced cost

New Bosch LB7 Injectors

New Bosch injectors are available and are the premium option. They carry a factory Bosch warranty and are brand-new production units. For most truck owners, the price premium over a quality reman set doesn’t deliver a meaningful performance or longevity difference. We typically recommend new Bosch injectors for fleet or commercial applications where maximum warranty coverage is prioritized.

What to Avoid

Be extremely cautious with:

- Unbranded “remanufactured” injectors from unknown sources — these are often cleaned and resealed but not properly rebuilt

- Chinese-manufactured injectors sold as “OEM equivalent” — these do not meet Bosch specifications

- “Rebuilt” injectors without flow test data — if the seller can’t provide test results, the injectors haven’t been properly verified

Should You Replace All 8 Injectors or Just the Bad Ones?

Our strong recommendation: replace all 8 at once.Here’s why:

- Labor overlap. The LB7 injector job is 8–12 hours of labor. Doing half now and half later means paying that labor cost twice.

- Matched performance. New or remanufactured injectors deliver consistent fuel flow. Mixing new injectors with high-mileage originals creates an imbalance that affects idle quality, power delivery, and emissions.

- Cascade failure. If one injector has failed from internal wear, the others are likely close behind. They all have the same hours, same fuel, same operating conditions.

- Warranty simplicity. Replacing all 8 with matched units means one warranty covers the entire set.

Preventing Future LB7 Injector Failure

After investing in a new set of injectors, protect them:

Fuel Filtration

The factory fuel filter on the LB7 is adequate but not exceptional. Consider upgrading to a larger-capacity aftermarket fuel filtration system that includes a water separator. At minimum, change the factory fuel filter every 10,000–15,000 miles. Use quality Fleetguard, Donaldson, or ACDelco filters.

Fuel Additives

ULSD fuel has lower natural lubricity than the older high-sulfur diesel that these engines were designed around. A quality lubricity additive (Stanadyne Performance Formula, Hot Shot’s Secret Diesel Extreme, or Opti-Lube XPD) added at each fill-up provides meaningful protection to injector internals.

Water Separator Maintenance

Drain the water separator regularly — monthly at minimum, more often in humid climates or if fuel quality is inconsistent. Water is the fastest way to kill a common rail injector.

Don’t Ignore Early Symptoms

If you notice rough idle, smoke, or fuel consumption changes, diagnose it early. A single failed injector pumping excess fuel return puts additional strain on the CP3 pump and can accelerate wear on the remaining injectors.

Frequently Asked Questions

How much does it cost to replace LB7 injectors?

Total cost for a complete 8-injector replacement on a 2001–2004 Duramax LB7 typically ranges from $3,200–$5,000 with professional installation using quality remanufactured Bosch injectors. The cost varies based on whether you use remanufactured or new injectors, and whether additional items (glow plugs, wiring harness, valve cover gaskets) are replaced at the same time. Valley Fuel Injection carries remanufactured LB7 injectors and can handle the complete job in our Woodland, CA shop.

How do I know which LB7 injectors are bad?

The definitive test is a fuel return rate measurement. Each injector’s return fuel volume is measured at idle and compared to specification. Injectors returning significantly more fuel than spec (over ~70-80 mL/min at idle) have failed internal seals. A qualified diesel shop with proper measuring equipment can perform this test in about an hour. Diagnostic trouble codes (P0201–P0208, P0300–P0308) can also point to specific cylinders, but return rate testing is the gold standard.

Are remanufactured LB7 injectors as good as new?

When remanufactured by a Bosch-authorized facility with proper test equipment, yes. A quality reman injector is completely disassembled, rebuilt with new or reconditioned components, and tested to the same flow and spray pattern specifications as a new unit. At VFI, our remanufactured Duramax injectors are tested on Bosch-certified equipment and carry a 12-month unlimited mileage warranty. The important thing is buying from a reputable source, not the cheapest option on the internet.

Can I replace just one or two LB7 injectors instead of all eight?

Technically yes, but we strongly recommend against it for the LB7 specifically. The labor to access LB7 injectors requires valve cover removal (8–12 hours), so doing the job twice costs far more than doing all 8 at once. Additionally, mixing new injectors with worn ones creates fuel delivery imbalances that affect idle, power, and efficiency. If one has failed from wear, the rest are likely close behind.

How long do LB7 injectors last?

Original LB7 injectors typically last 100,000–200,000 miles, though some fail earlier and some last longer depending on fuel quality, maintenance, and operating conditions. With proper fuel filtration, quality fuel, and regular maintenance, a set of remanufactured or new Bosch injectors should deliver comparable service life.

Ready for Your LB7 Injector Replacement?

Whether you need a set of remanufactured Bosch LB7 injectors shipped to your shop or home, or you want our Bosch-certified technicians to handle the complete replacement in our Woodland, CA facility — we’re here to help.

We also service injectors for all other Duramax variants (LLY, LBZ, LMM, LML, L5P) as well as Cummins, Powerstroke, and industrial applications. See our full diesel fuel injection services page for details.

Call us: (530) 668-0818Email: info@vfidiesel.comVisit: 1243 E Beamer St, Suite C, Woodland, CA 95776Shop Duramax Injectors: vfidiesel.com/product-category/diesel-injectors/duramax/Valley Fuel Injection & Turbo, Inc. is an authorized dealer for Bosch, Kubota, Delphi, Yanmar, and Alliant Power. Located in Woodland, CA, we serve diesel owners and fleets throughout Northern California and nationwide via our mail-in repair and parts shipping services.