Stanadyne DB2 & DB4 Injection Pump Rebuild: Complete Guide

22 February 2026

Best Diesel Fuel Additive: What Actually Works (From Injection Experts)

22 February 2026Professional Diesel Injector Testing — From Anywhere in the U.S.

Not every diesel shop has the equipment to properly test fuel injectors. Most don’t. That’s why customers from coast to coast ship their injectors to Valley Fuel Injection & Turbo for testing on factory-grade equipment that delivers actual diagnostic data — not guesswork.

Whether you’re a fleet mechanic in Texas trying to isolate a miss on a Cummins ISX, a farmer in Iowa with a rough-running John Deere, or a truck owner in Florida chasing a no-start condition on your Powerstroke — you can box up your injectors, ship them to our lab in Woodland, California, and get a professional test report back telling you exactly which injectors are good, which are marginal, and which need replacement.

What We Test

We test virtually every type of diesel fuel injector in service today — and plenty that haven’t been manufactured in decades. Our test capabilities cover:

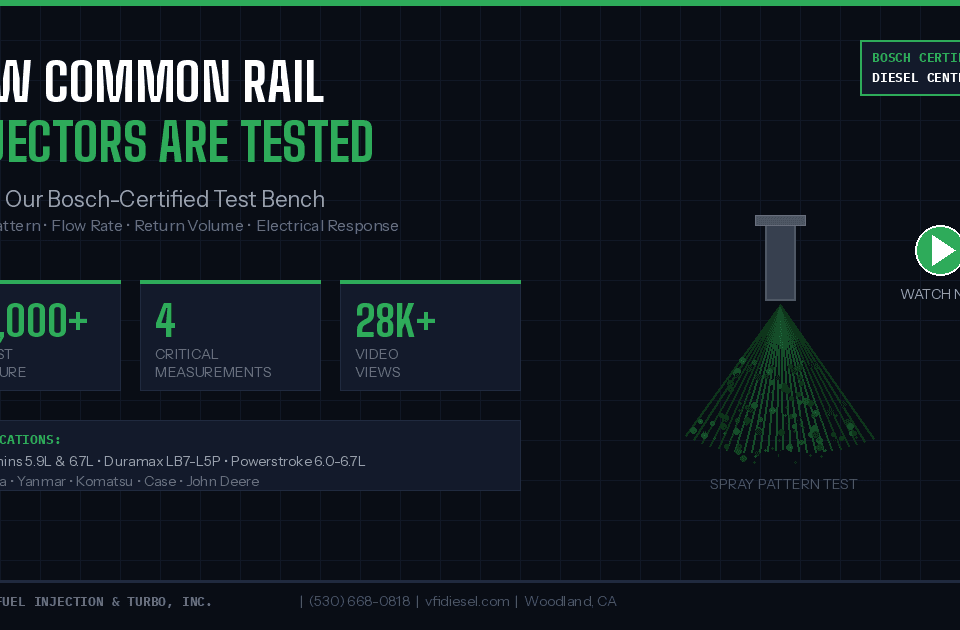

Common Rail Injectors

Modern high-pressure common rail injectors operate at 25,000-30,000+ PSI and require specialized test benches that can replicate those pressures while measuring fuel delivery in fractions of a cubic centimeter. We test common rail injectors for Bosch, Denso, Delphi, and Siemens/Continental systems across all major platforms:

- Cummins: 5.9L (2003-2007) and 6.7L ISB, ISC, ISL, ISX, ISB 4.5, QSB, QSK

- Duramax: LB7, LLY, LBZ, LMM, LML, L5P

- Powerstroke: 6.0L, 6.4L, 6.7L

- Sprinter: 2.7L and 3.0L CDI

- Agricultural/Industrial: John Deere, Kubota, Yanmar, Perkins, Caterpillar, Deutz, Doosan

Our common rail test procedure measures fuel delivery at multiple RPM points, return fuel flow (a key indicator of internal wear), solenoid response time, spray pattern quality, nozzle seat leakage, and opening pressure. Each injector gets a detailed pass/fail report with measured values compared against the manufacturer’s specification.

HEUI Injectors (Hydraulic Electronic Unit Injectors)

HEUI injectors — used in the Ford 7.3L Powerstroke, 6.0L Powerstroke, International/Navistar T444E, DT466E, VT365, and some Caterpillar engines — are hydraulically actuated and electronically controlled. Testing requires equipment that can supply high-pressure oil while simultaneously controlling the electronic firing signal. We test for spool valve response, injection quantity, return oil flow, and electrical performance.

Mechanical Injectors (Nozzle and Holder)

Traditional mechanical injectors found on older diesel engines use a simple spring-loaded nozzle that opens at a set pressure. Despite their simplicity, worn nozzles cause poor atomization, smoke, reduced power, and increased fuel consumption. We test opening pressure (pop pressure), spray pattern, seat leakage (drip test), and nozzle chatter using a calibrated nozzle pop tester. Common applications include older Cummins (5.9L 12-valve, N14 mechanical, 855), John Deere, Kubota, Yanmar, Perkins, Deutz, and International.

Electronic Unit Injectors (EUI)

Electronic unit injectors are mechanically actuated by a camshaft rocker and electronically controlled for timing and fuel quantity. Found on Caterpillar 3406E, C10, C12, C13, C15, C16; Detroit Diesel Series 60; Cummins CELECT (N14, M11); and Volvo engines. Testing measures solenoid electrical performance, fuel delivery at multiple pulse widths, return fuel flow, and mechanical operation.

Pencil-Type and Agricultural Injectors

Many agricultural and small diesel engines use pencil-type injectors — slim, single-piece designs common on John Deere, Kubota, Yanmar, Massey Ferguson, Ford/New Holland, and Perkins engines. We test these for opening pressure, spray quality, and leakage. If you need help bleeding the fuel system after reinstalling tested injectors, we have guides available.

What Our Testing Tells You

A professional injector test isn’t just a pass/fail stamp. Here’s what you actually learn from our test reports:

Fuel delivery volume. How much fuel each injector delivers at specified RPM points. If one injector is delivering 15% more or less than the others, that’s your miss, your rough idle, or your power imbalance — even if all injectors individually “pass.” Cylinder-to-cylinder balance often matters more than absolute delivery numbers.

Return fuel flow. On common rail and HEUI injectors, return fuel (fuel that leaks internally past the control valve or nozzle needle and returns to the tank) is a critical measurement. Excessive return flow means the high-pressure pump is working harder to maintain rail pressure, and the injector is losing fuel that should be going into the cylinder. This is the #1 indicator of common rail injector wear.

Spray pattern and atomization. A healthy injector produces a fine, even cone of atomized fuel. A worn nozzle produces streams, drips, or uneven spray that causes incomplete combustion, smoke, and hot spots on piston crowns. We visually inspect spray patterns on mechanical injectors and measure the effect of poor atomization through delivery and return flow data on electronic injectors.

Electrical performance. For all electronically controlled injectors, we verify solenoid resistance, inductance, response time, and current draw. An injector can be mechanically perfect but electrically out of spec — or vice versa. Both sides need to check out.

Nozzle seat leakage. After the injector fires, the nozzle must seal completely. Leakage at the seat allows fuel to dribble into the cylinder after injection, causing smoke, carbon buildup, and washed cylinder walls (fuel diluting the oil film). Our test holds the injector at pressure below opening pressure and measures any leakage over time.

How Much Does Injector Testing Cost?

Testing costs vary by injector type and the level of testing required:

| Injector Type | Test Cost (per injector) | Notes |

|---|---|---|

| Mechanical / Pencil-Type | $25 – $40 | Pop test, spray pattern, leak test |

| Common Rail (Bosch, Denso, Delphi) | $40 – $75 | Full electronic test, delivery, return flow |

| HEUI (7.3L, 6.0L, T444E, DT466) | $40 – $75 | High-pressure oil actuation test |

| Electronic Unit (Cat, Detroit, Cummins) | $40 – $75 | Solenoid and mechanical test |

Most customers send a complete engine set (6 or 8 injectors) for testing. This lets us evaluate cylinder-to-cylinder balance, which is often more diagnostic than testing a single injector in isolation. Volume pricing is available for fleets and shops sending multiple sets.

If injectors fail testing, we can provide remanufactured replacements or rebuild your existing injectors (where applicable). We’ll contact you with the test results and options before any additional work is performed.

How to Ship Your Injectors

Sending injectors for testing is straightforward. Follow these steps to ensure your injectors arrive safely and we can process them efficiently:

Step 1: Contact Us First

Call (530) 668-0818 or email to let us know what you’re sending. Tell us the engine make, model, and year, what symptoms you’re experiencing, and how many injectors are in the set. This lets us prepare and prioritize your order.

Step 2: Prepare the Injectors

Remove carefully. Keep track of which cylinder each injector came from — label them 1 through 6 (or 8) in firing order. If testing reveals one bad injector, knowing which cylinder it was in confirms the diagnosis against your symptoms.

Cap or plug all openings. The fuel inlet, return line connection, and nozzle tip should all be capped or covered. Dirt and debris that enter through open ports can damage precision internal surfaces during shipping. Rubber caps, clean tape, or even plastic bags with rubber bands work fine.

Don’t clean excessively. A quick wipe-down is fine, but don’t blast injectors with solvents or use wire brushes on the nozzle tips. Some carbon buildup actually helps us diagnose spray pattern issues. We’ll ultrasonically clean them as part of the test process.

Step 3: Pack and Ship

Wrap each injector individually in bubble wrap, foam, or heavy paper. Injectors banging against each other in a box can damage nozzle tips — which are ground to a needle-point finish.

Use a sturdy box with adequate packing material. A set of 8 common rail injectors weighs 10-15 pounds — don’t underpack.

Include your contact information and a note describing the symptoms and which injector came from which cylinder.

Ship to:

Valley Fuel Injection & Turbo

1575 East St

Woodland, CA 95776

UPS, FedEx, and USPS all work. Fuel injectors are not hazardous material (unlike injection pumps with residual fuel), so no special shipping labels are needed.

Step 4: We Test and Report

Once received, your injectors are logged, tested on the appropriate bench, and a detailed report is generated. We’ll call or email you with results, typically within 2-5 business days of receiving the shipment. The report includes measured values for each injector, pass/fail status against manufacturer specs, and our recommendations.

Step 5: Return or Replace

Good injectors are returned to you. Failed injectors can be replaced with remanufactured units, rebuilt (where applicable), or returned as-is — your choice. We ship tested injectors back in protective packaging via your preferred carrier.

Why Ship Injectors for Testing Instead of Just Replacing Them?

A set of 8 new common rail injectors can cost $2,000 to $6,000+ depending on the platform. Testing the existing set costs a fraction of that and tells you exactly which injectors (if any) actually need replacement. Here are the scenarios where testing saves real money:

Rough idle or miss on one cylinder. Instead of replacing all 6 or 8 injectors, testing identifies the one or two that are out of spec. Replace only what’s needed.

High return fuel flow. Your common rail system is losing rail pressure, and the high-pressure pump is working overtime. Is it one injector dumping return fuel, or are they all marginal? Testing tells you exactly where the fuel is going.

Post-repair verification. You replaced a head gasket, did injector cups, or had other engine work done. Before buttoning everything up, test the injectors to avoid tearing it apart again in 6 months.

Used engine or equipment purchase. Buying a used truck or tractor? Testing the injectors before purchase (or immediately after) gives you a baseline and avoids surprises.

Fleet maintenance. Proactive injector testing at scheduled service intervals catches marginal injectors before they fail in the field, preventing tow bills, downtime, and secondary damage from running on bad injectors.

What Happens If Injectors Fail Testing?

If one or more injectors don’t meet specification, you have options:

Remanufactured replacement. We stock remanufactured injectors for most popular platforms. These are professionally rebuilt to OEM specifications and are typically 40-60% less than new dealer pricing. We can install them and return your complete set ready to go.

Injector rebuild. Some injector types can be rebuilt — new nozzle, seals, and internal components installed in your existing injector body. This is common for mechanical injectors, some HEUI injectors, and certain electronic unit injectors. Not all injector types are rebuildable — some common rail injectors are sealed assemblies that can only be replaced.

Return as-is. If you want to source your own replacements, we’ll return the tested set with the report so you know exactly what you need. No pressure, no markup on parts you don’t want.

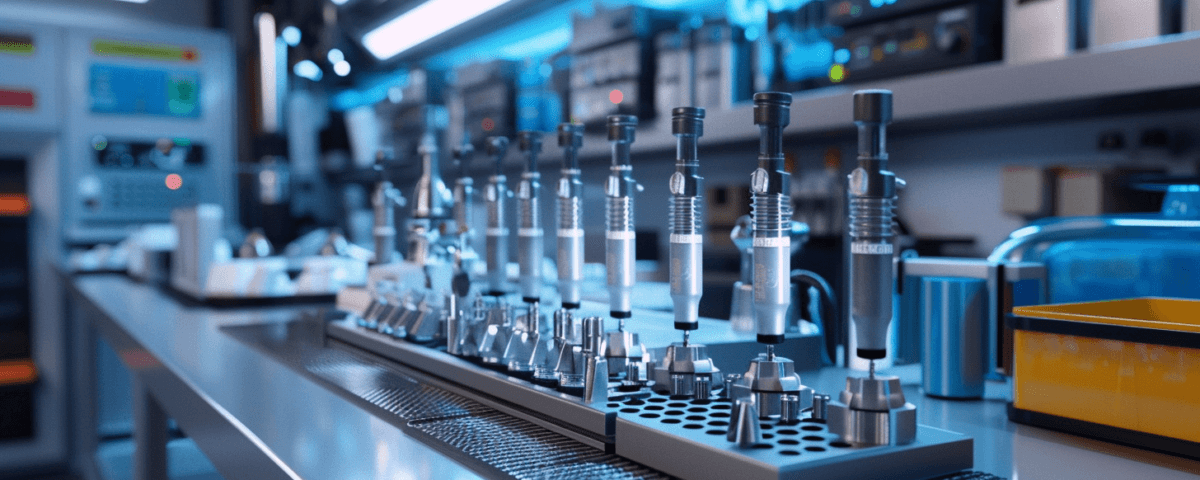

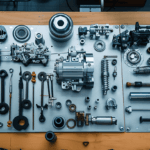

Equipment We Use

Our injector testing lab isn’t a guy with a pop tester on a bench. We use factory-grade equipment from the same manufacturers who built the injectors:

Bosch EPS test bench — the industry standard for common rail injector testing. Replicates actual fuel system pressures (up to 30,000+ PSI) and measures delivery with laboratory precision. This is the same equipment Bosch dealers and injector remanufacturers use worldwide.

HEUI test equipment — dedicated bench that supplies high-pressure oil at controlled temperatures while firing the injector electronically. Replicates the actual operating conditions inside a HEUI engine.

Calibrated nozzle pop testers — for mechanical injectors, we use precision pop testers that verify opening pressure to the exact PSI specification, evaluate spray pattern quality, and measure seat leakage duration.

Ultrasonic cleaning system — before testing, injectors go through our ultrasonic cleaning bath to remove carbon deposits, varnish, and contamination that could affect test results. This gives us a true reading of the injector’s mechanical condition, not just how dirty it is.

This equipment represents a significant investment — well over $100,000 — which is exactly why most general repair shops don’t offer injector testing. When you ship your injectors to us, you’re getting access to a purpose-built fuel injection laboratory that tests and calibrates injectors and injection pumps as our core business.

Who Uses Our Mail-In Service?

Our mail-in testing isn’t just for individual truck owners. We serve:

Independent diesel shops that don’t have injector test equipment in-house. Many shops ship injectors to us regularly as part of their diagnostic workflow — it’s faster and cheaper than buying their own test bench.

Fleet maintenance operations running scheduled injector testing on their Cummins, Duramax, and Powerstroke trucks. Proactive testing extends injector life and prevents roadside failures.

Farmers and agricultural operations maintaining their own tractor fleets. When a tractor injection pump is pulled for rebuild, the injectors should be tested at the same time.

Marine diesel operators maintaining boat and yacht engines where injector access requires significant labor — test before reinstalling to avoid pulling the engine apart again.

Equipment dealers and auctioneers verifying injector condition on used equipment before sale.

Frequently Asked Questions

How long does mail-in injector testing take?

Typical turnaround is 2-5 business days from when we receive your injectors. This includes intake, cleaning, testing, and report generation. We’ll contact you with results as soon as testing is complete. If you need rush service, call us at (530) 668-0818 to discuss your timeline.

Should I send all my injectors or just the one I think is bad?

Send the complete set whenever possible. Testing all injectors lets us evaluate cylinder-to-cylinder balance, which is often more revealing than testing a single injector in isolation. An injector that passes by itself might be significantly off compared to the rest of the set, causing a perceptible imbalance in the engine. Testing the full set costs less per injector and gives you a complete picture.

Do I need to label which cylinder each injector came from?

Yes — label each injector with its cylinder number before removing it. Use a paint marker or masking tape. If testing reveals a failed injector, knowing which cylinder it was in helps confirm the diagnosis against your engine’s symptoms (which cylinder was missing, where the smoke was coming from, etc.). It also ensures injectors go back in the correct position if they pass testing.

Are fuel injectors hazardous to ship?

No. Unlike injection pumps that hold residual fuel, individual fuel injectors contain minimal fuel residue and are not classified as hazardous material for shipping. You can ship via UPS, FedEx, or USPS without special labels or declarations. Just wrap each injector to prevent damage and use a sturdy box.

Can you test and rebuild injectors for older tractors?

Absolutely. We test and rebuild mechanical injectors for virtually every make — John Deere, Kubota, Yanmar, Massey Ferguson, Ford, Case IH, International, Perkins, Deutz, Caterpillar, and more. Many of these older pencil-type and pintle injectors can be rebuilt with new nozzles and springs for a fraction of replacement cost. We’re also a Stanadyne factory-authorized dealer for tractor injection pump rebuilds.

How do I know if my injectors are the problem vs. the injection pump?

Common symptoms can overlap. Generally, a single-cylinder miss or one cylinder with different exhaust color points to an injector issue. Engine-wide symptoms like across-the-board power loss, hard starting, or erratic idle are more likely pump-related. On common rail systems, low rail pressure with normal injector return flow suggests a pump issue, while high return flow from one or more injectors points to worn injectors. If you’re unsure, call us — we can often help narrow it down over the phone before you start pulling parts.

Ship Your Injectors for Professional Testing

Valley Fuel Injection & Turbo provides factory-grade diesel injector testing for common rail, HEUI, mechanical, and electronic unit injectors. Ship from anywhere in the United States.

📞 (530) 668-0818

📍 1575 East St, Woodland, CA 95776

🕐 Monday – Friday, 8:00 AM – 5:00 PM

Ship to: Valley Fuel Injection & Turbo, 1575 East St, Woodland, CA 95776

Local service: Woodland · Sacramento · Davis · Vacaville · Yuba City · Stockton · Chico · Redding