Diesel Turbocharger Failure: 8 Warning Signs & What to Do

22 February 2026

Stanadyne DB2 & DB4 Injection Pump Rebuild: Complete Guide

22 February 2026Published by Valley Fuel Injection & Turbo, Inc. | Woodland, CA

Factory-Authorized Service Center for Bosch, Stanadyne, Delphi, Denso & Yanmar

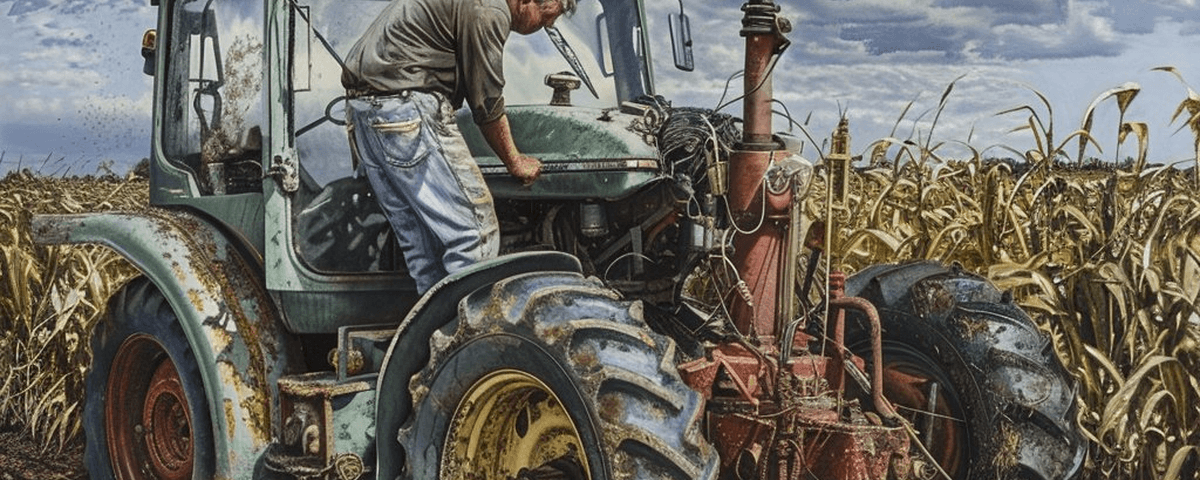

When a tractor injection pump fails — rough running, losing power under load, excessive smoke, hard starting, or no start at all — you’re facing a decision that affects your equipment, your season, and your bottom line. Do you rebuild it? Replace it with a remanufactured exchange? Buy new? And who do you trust with a precision component that operates at tolerances measured in thousandths of an inch?

At Valley Fuel Injection & Turbo, we’ve been rebuilding and calibrating tractor injection pumps for over 30 years — Stanadyne, Bosch, CAV/Lucas, Delphi, Zexel, and more. We’re a factory-authorized service center with state-of-the-art test stands, and we serve farmers and equipment owners both locally in California’s Central Valley and nationwide through our mail-in rebuild service.

This guide covers everything you need to know about tractor injection pump rebuilds: how to tell when your pump needs service, what the rebuild process actually involves, what it costs, how to ship your pump to us from anywhere in the country, and why a proper rebuild from a certified shop beats a cheap aftermarket replacement every time.

Signs Your Tractor Injection Pump Needs Rebuilding

Injection pumps don’t usually fail all at once. They wear gradually, and the symptoms build over time. Here’s what to watch for:

Hard starting or extended cranking. The pump can no longer build enough pressure on the first few revolutions to fire the injectors. This is often worse in cold weather, when fuel is thicker and the pump has to work harder. If your tractor used to start in 2–3 seconds and now takes 10–15 seconds of cranking, the pump’s internal components are wearing.

Loss of power under load. The tractor runs fine at idle or light work, but bogs down when you ask it to pull — discing, plowing, running a PTO-driven implement. The pump can’t deliver enough fuel at full governor demand because of worn plungers, eroded delivery valves, or internal bypass from worn sealing surfaces.

Rough running or misfiring. If the pump delivers uneven fuel to each cylinder — one getting more, another getting less — the engine runs rough. On an inline pump, this usually means individual plunger-and-barrel sets have worn unevenly. On a rotary pump (Stanadyne DB2/DB4, CAV DPA), the distributor rotor or head-and-rotor assembly may be worn.

Black or white exhaust smoke. Black smoke means excessive or poorly timed fuel delivery — the pump is dumping too much fuel or delivering it at the wrong point in the cycle. White smoke (especially on cold startup that doesn’t clear up) can indicate retarded injection timing or worn delivery valves that can’t maintain pressure.

Fuel leaking from the pump. External fuel leaks from shaft seals, gaskets, or fittings indicate seal failure. On Stanadyne rotary pumps, a leaking front shaft seal is one of the most common issues — and if left unaddressed, diesel fuel dilutes your engine oil, which can cause bearing damage to the engine itself.

Erratic idle speed or hunting. The governor inside the pump regulates idle speed. When governor components wear — springs, weights, sleeve — the idle becomes unstable, surging up and down (“hunting”). This is extremely common on older Stanadyne DB and JDB pumps where the original plastic governor weight retainer ring deteriorates.

Fuel in the engine oil. If you’re checking your dipstick and the oil level is rising — or the oil smells like diesel — fuel is leaking past internal seals in the pump and entering the engine crankcase through the pump drive. This is a “fix it now” situation because diesel fuel destroys oil film strength and can cause rapid engine bearing wear.

What Types of Tractor Injection Pumps Does VFI Rebuild?

We rebuild virtually every type of diesel injection pump used in agricultural equipment. Here’s a breakdown by manufacturer and pump type:

Stanadyne / Roosa Master Rotary Pumps

If your tractor was built by John Deere, Case/IH, Ford/New Holland, or International Harvester and it’s from the 1960s through the early 2000s, there’s a very good chance it has a Stanadyne pump (originally called Roosa Master — same company, different name). These are rotary distributor-type pumps that are compact, reliable, and ubiquitous in agriculture.

Common models we rebuild:

- DB2 — the workhorse of agricultural injection. Found on John Deere 4039/4045 engines, Case 188/207 engines, Ford tractor diesels, GM 6.2L/6.5L, and dozens of other applications

- DB4 — updated version with advance mechanism improvements. Common on later John Deere, Case/IH, and Perkins engines

- JDB — John Deere-specific variant with integrated governor configurations for specific JD tractor models

- DM4 — mechanical distributor pump for larger agricultural engines

Stanadyne pump rebuilds typically include: complete seal and gasket kit, head-and-rotor inspection and replacement if worn, solid metal weight retainer upgrade (replacing the problematic plastic ring), governor component inspection, advance mechanism service, and full calibration on our Stanadyne-certified test stand.

Bosch Inline (Jerk) Pumps

Bosch inline pumps — also called P-pumps, A-pumps, M-pumps, or MW-pumps depending on size — are the gold standard for larger agricultural engines. These are mechanical marvels: each cylinder gets its own plunger-and-barrel pumping element, all driven by a common camshaft inside the pump housing. They’re found on John Deere 6-cylinder tractors, Case/IH Magnum series, older Cummins-powered agricultural equipment, and a wide range of industrial and construction engines.

What makes inline pumps special is their modularity — individual pumping elements can be replaced without scrapping the entire pump. A proper rebuild includes:

- Individual plunger-and-barrel testing and replacement as needed

- Delivery valve inspection and replacement

- Governor overhaul (RSV, RQ, or RQV type)

- Camshaft and roller tappet inspection

- Complete reseal with genuine Bosch seals

- Full calibration on our Bosch-certified multi-cylinder test stand

We’re part of the Bosch Diesel Network — factory-authorized to test, rebuild, and calibrate Bosch injection pumps to original specifications using Bosch-certified equipment and genuine parts.

CAV / Lucas / Delphi Rotary Pumps

British-made CAV and Lucas DPA (Distributor Pump type A) and DPS pumps are found on a huge range of agricultural equipment — particularly Ford/Fordson tractors, Massey Ferguson, David Brown, Leyland, Perkins-powered equipment, and many European imports. Delphi is the current manufacturer (having acquired the Lucas diesel division), and we’re authorized to service all generations.

Common models we rebuild:

- DPA — the most common CAV pump in agriculture. Compact rotary design found on millions of tractors worldwide

- DPS — updated version with electronic advance on some models

- DPCN / DPCK — later Delphi variants

CAV/Lucas pumps are known for their tight tolerances and sensitivity to fuel quality. A proper rebuild requires specialized CAV tooling and test equipment — which is why many general mechanics won’t touch them. We have the factory-authorized equipment and training to rebuild these pumps to original specifications.

Other Pump Types We Service

- Zexel (formerly Diesel Kiki) — found on Kubota, Mitsubishi, and some Caterpillar equipment

- Denso — common on Kubota and Yanmar engines

- Ambac / American Bosch — older Allis-Chalmers, some International, military applications

- Common rail high-pressure pumps — CP1, CP2, CP3, and CP4 pumps on newer Tier 4 agricultural engines

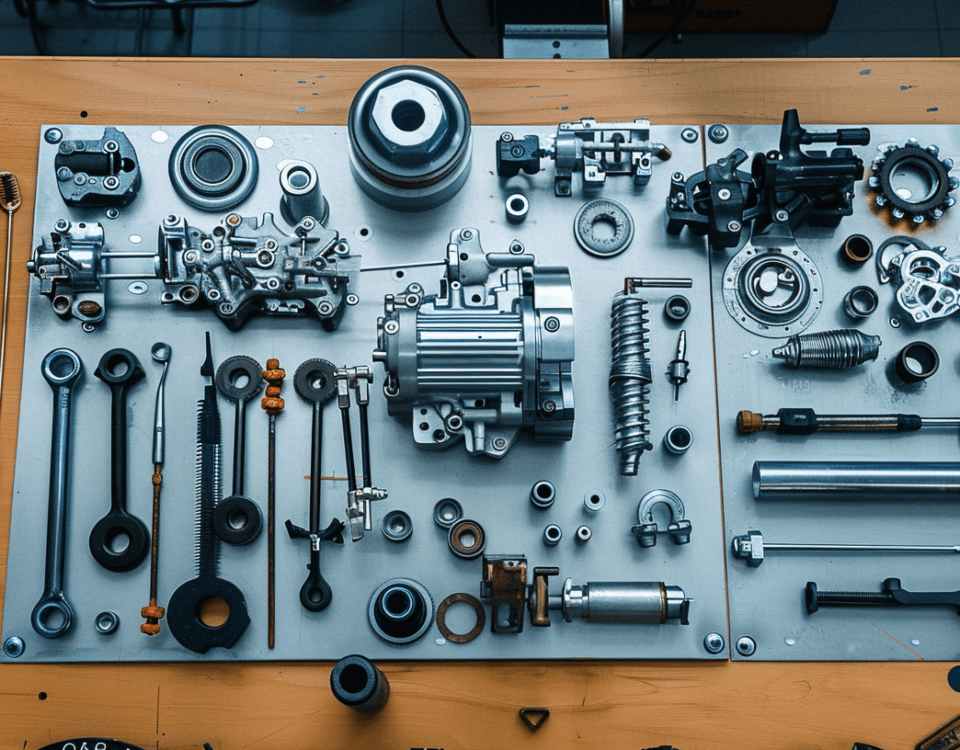

The Rebuild Process: What Actually Happens to Your Pump

A professional injection pump rebuild is not just a seal kit replacement. It’s a complete teardown, inspection, and restoration to factory specifications. Here’s what happens when your pump arrives at our shop:

1. Initial testing and documentation. Before we touch anything, we test the pump on our calibration stand in “as-received” condition. This gives us a baseline — we can see exactly what’s wrong and how far it’s drifted from specification. We document everything: fuel delivery per cylinder, timing, governor response, advance function, return fuel rates.

2. Complete disassembly. The pump is fully disassembled in a clean environment. Every component is laid out, cleaned, and inspected. Diesel injection components are machined to extremely tight tolerances — we’re talking clearances of 0.0001″ to 0.0004″ on plunger-and-barrel fits. A single speck of debris can score these surfaces, so cleanliness is critical throughout the process.

3. Inspection and measurement. Every wear component is measured against factory specifications: plunger-and-barrel clearances, delivery valve seats, rotor-to-housing clearances (on rotary pumps), governor weight and sleeve dimensions, camshaft lobe profiles (on inline pumps), advance mechanism components. Parts that are within spec are reused. Parts that are worn beyond spec are replaced.

4. Parts replacement. Worn components are replaced with genuine OEM or OEM-equivalent parts. This typically includes: complete seal and gasket kit, plunger-and-barrel assemblies (if worn), delivery valves, governor components as needed, bearings, and any application-specific upgrades (like the metal weight retainer for Stanadyne pumps).

5. Reassembly. The pump is reassembled to factory specifications using specialized tools and fixtures. Torque values, shimming, and internal adjustments are set precisely — this isn’t a job for impact wrenches and guesswork.

6. Calibration on the test stand. This is the most critical step and the one that separates a professional rebuild from a “seal kit and prayer” job. The reassembled pump is mounted on our calibration test stand — a machine that drives the pump at various speeds while measuring fuel delivery from every outlet simultaneously. We set:

- Fuel delivery volume per cylinder (at multiple RPMs)

- Cylinder-to-cylinder balance (ensuring even delivery across all outputs)

- Governor speed regulation (idle, high idle, and governor cutoff)

- Injection timing and advance curve

- Return fuel rates (indicating internal leakage/clearance)

All settings are calibrated to the exact factory specifications for your specific pump code number. Every pump has a unique calibration code — it’s the alphanumeric number stamped on the data plate (like “DB2831-4911” or “PES6A95D410LS2532”). This code tells us the exact fuel delivery, timing, and governor settings that your engine was designed to run with.

7. Final testing and quality verification. After calibration, we run the pump through a final acceptance test, verifying all parameters are within specification. The pump is then preserved, sealed, and either prepared for local pickup or packed for return shipping.

How Much Does a Tractor Injection Pump Rebuild Cost?

Costs vary significantly by pump type, the extent of internal wear, and which parts need replacing. Here are typical ranges:

| Pump Type | Rebuild Cost (parts + labor) | Notes |

|---|---|---|

| Stanadyne DB2/DB4 rotary | $400–$900 | Seal kit rebuild on lower end; head & rotor replacement on higher end |

| Stanadyne JDB/DM4 | $500–$1,200 | JDB pumps vary widely by application complexity |

| Bosch inline 4-cylinder | $600–$1,200 | Depends on number of plunger/barrel sets needed |

| Bosch inline 6-cylinder | $800–$1,800 | Larger pump = more elements to inspect/replace |

| CAV/Lucas DPA | $500–$1,000 | Specialized tooling required; head & rotor is the main cost driver |

| Delphi DPS/DPCN | $500–$1,200 | Electronic advance models toward higher end |

| Common rail (CP3, CP4) | $800–$2,000+ | Higher pressure systems require more expensive components |

These are rebuild costs — where we work on your pump and return it to you. If your pump is too far gone to rebuild (cracked housing, severely scored bore, etc.), we can usually provide a remanufactured exchange unit at a competitive price. Exchange units are rebuilt pumps from our inventory that are ready to ship immediately — you send your old pump back as a core.

VFI’s Nationwide Mail-In Rebuild Service

You don’t have to be in California to use our services. We accept injection pumps and injectors from all 50 states through our mail-in rebuild program. Here’s how it works:

Step 1: Contact us. Call (530) 668-0818 or send us a message with your pump make/model, the data plate number (stamped on the pump), your tractor make/model/year, and a description of the symptoms. We’ll give you a preliminary estimate and shipping instructions.

Step 2: Ship your pump. Remove the pump from your tractor (or have your local mechanic do it). Cap all open fittings with plastic plugs or tape to keep debris out. Pack the pump securely in a sturdy box with plenty of padding — these are heavy, precision components. Ship via UPS Ground or FedEx Ground. We recommend insuring the shipment for the replacement value of the pump.

Step 3: We test, evaluate, and call you. When your pump arrives, we test it on our calibration stand and provide a detailed assessment. We’ll call you with exactly what we found, what needs to be replaced, and a firm quote. No surprises — you approve the work before we start.

Step 4: Rebuild and calibration. Once approved, we rebuild and calibrate your pump. Typical turnaround is 5–10 business days from approval, though we can expedite for in-season emergencies when possible. We understand that during planting and harvest, every day your equipment is down costs money.

Step 5: Return shipping. Your rebuilt, calibrated pump is packed securely and shipped back to you. We include a test report showing the calibration results so you have documentation of exactly how the pump was set.

Rebuild vs. Exchange vs. New: Which Option Is Best?

Rebuild your own pump when: the pump is in rebuildable condition (no cracked housing or catastrophic internal failure), you want your original pump back with the exact same configuration, or cost is a primary concern. Rebuilds are typically the most economical option.

Exchange for a remanufactured unit when: you need the tractor running immediately and can’t wait for a rebuild, your pump is damaged beyond rebuild (cracked housing, severely scored components), or you want a tested, ready-to-install unit right away. Exchange pumps ship immediately — you install the rebuilt one and send your old pump back as a core return.

Buy new when: the pump is an obsolete model with no available rebuild parts, or the application requires a factory-fresh unit (rare in agricultural applications). New OEM pumps are significantly more expensive — often 3–5x the cost of a quality rebuild — and for most agricultural applications, a professionally rebuilt pump delivers identical performance and longevity.

Why You Should Never Run a Worn Injection Pump

A worn injection pump doesn’t just affect the pump — it creates a cascade of problems throughout the engine:

- Injector damage. A pump that’s delivering inconsistent or poorly timed fuel wears injector nozzles faster. Rebuilding the pump but running it with worn injectors means the engine still runs poorly. We recommend testing your injectors any time the pump is being rebuilt — the cost of testing is minimal compared to reinstalling a rebuilt pump only to find the injectors are shot.

- Increased fuel consumption. A pump that’s over-delivering fuel (common as internal clearances increase) burns more diesel than necessary. On equipment that runs all day during planting or harvest season, this adds up fast.

- Engine damage from retarded timing. A worn advance mechanism delivers fuel late in the combustion cycle, causing excessive exhaust temperatures that can crack pistons, burn valves, and damage turbochargers.

- Oil contamination. As mentioned earlier, fuel leaking past internal pump seals into the engine crankcase dilutes your oil and can cause catastrophic engine bearing failure. A $600 pump rebuild prevents a $10,000+ engine rebuild.

Central Valley Agriculture: Why VFI Understands Your Equipment

Located in Woodland, CA — the heart of California’s agricultural country — we’ve been serving farmers, ranchers, and agricultural operations for over three decades. We understand that equipment downtime during planting, irrigation, or harvest isn’t just inconvenient — it’s a direct threat to your livelihood.

Our shop works on the equipment you actually run: John Deere row-crop tractors, Case/IH combines, Kubota compact tractors, older Ford and Massey Ferguson workhorses that have been running for 30+ years and still have plenty of life left with proper fuel system maintenance. We stock common parts for the most popular agricultural pumps, and our relationships with Bosch, Stanadyne, and Delphi mean we can source hard-to-find components for older equipment that other shops can’t get.

Don’t Forget the Injectors

The injection pump and injectors are a matched system. A freshly rebuilt pump paired with worn injectors will still run poorly — the pump can deliver perfect fuel volume and timing, but if the injectors can’t atomize it properly, combustion suffers.

We strongly recommend having your injectors tested whenever the pump is being rebuilt. Our injector test benches evaluate spray pattern, opening pressure, fuel delivery volume, and tip leakage. Injectors that pass testing get new seals and go back in. Injectors that fail can be rebuilt (mechanical nozzle-type) or replaced with remanufactured units. Testing the complete set typically costs $30–$75 per injector — a fraction of the labor cost to pull the pump and injectors a second time if you skip it now.

Need a tractor injection pump rebuilt? Ship it to us from anywhere.

VFI is factory-authorized for Bosch, Stanadyne, Delphi, Denso, and Zexel. We rebuild pumps for John Deere, Case/IH, Ford/New Holland, Massey Ferguson, Kubota, Yanmar, Caterpillar, and more.

Call (530) 668-0818 or contact us online for a quote.

Valley Fuel Injection & Turbo, Inc.

1243 E Beamer St, Suite C, Woodland, CA 95776

Monday–Friday, 7:00 AM – 4:30 PM PST

Serving farmers and equipment owners locally in Sacramento, Woodland, Davis, Stockton, Chico, Yuba City, Redding, and Reno — and nationwide through our mail-in service.

Related reading: Bosch Diesel Injection: Pumps, Injectors, Testing & Repair · How to Test Diesel Fuel Injectors · Diesel Injector Failure Symptoms · Kubota Engine Sales, Parts & Service · Yanmar Engine Parts & Service · VP44 Injection Pump Failure · CP4 Injection Pump Failures · Diesel Cranks But Won’t Start