CP4 Injection Pump Failures: Symptoms, Causes, Repair Costs, Prevention

01/14/2026

5.9 Cummins VP44 Injection Pump Failure: Complete Diagnosis & Repair Guide

02/16/2026Published by Valley Fuel Injection & Turbo, Inc. | Woodland, CA

Authorized Kubota Engine Dealer & Bosch-Certified Diesel Specialists

Since Kubota transitioned to Tier 4 Final emissions standards, injector-related failures have become one of the most common and most expensive problems owners face. Engines like the V2403, V3307, V2607, and V3800 deliver excellent power and emissions compliance — but their common rail injection systems are far less forgiving than the mechanical injectors used in older Kubota engines.

At Valley Fuel Injection & Turbo — an authorized Kubota engine dealer and Bosch-certified diesel injection center — we diagnose and repair Kubota Tier 4 injector failures every week. The machines come in from farms, construction sites, and commercial operations across Northern California: compact tractors that won’t start, skid steers blowing smoke, generators running rough.

The pattern is almost always the same: contaminated fuel, inadequate filtration, or operating conditions the injection system wasn’t designed to handle. This guide covers why Tier 4 Kubota injectors fail, the warning signs to watch for, what happens when problems are ignored, what repairs cost, and how to prevent the most common failures.

What Changed with Kubota Tier 4 Engines

Tier 4 Final emissions standards (phased in 2008–2015 depending on engine size) forced diesel manufacturers to dramatically reduce particulate matter (PM) and nitrogen oxide (NOx) emissions. To meet these requirements, Kubota made fundamental changes to how fuel is delivered and burned.

Pre-Tier 4 Kubota engines (D902, D1105, V1505, V2203, and similar) used indirect injection with mechanical injectors. These systems operated at lower pressures, had wider tolerances, and were remarkably forgiving of marginal fuel quality. A dirty fuel filter might cause rough running, but it rarely destroyed the injectors.

Tier 4 Kubota engines (V2403-CR, V3307-CR, V2607, V3800, and similar) use advanced common rail fuel injection with:

- Injection pressures exceeding 23,000 PSI — vs. 2,000–3,000 PSI on older mechanical systems

- Multiple injection events per combustion cycle — pilot, main, and post injection for emissions control

- Injector nozzle holes smaller than a human hair — precise enough to control fuel delivery within microseconds

- Diesel Particulate Filter (DPF) — requires periodic regeneration using post-injection fuel events

- EGR (Exhaust Gas Recirculation) — re-circulates exhaust to reduce NOx, increasing soot exposure on internal components

These systems deliver impressive emissions performance, but they’ve traded the old Kubota’s bulletproof simplicity for precision that demands clean fuel, consistent operation, and more attentive maintenance.

Why Injectors Fail in Kubota Tier 4 Engines

Tier 4 Kubota injector failures rarely come from a single cause. In our shop, the pattern is almost always a combination of fuel quality issues, operating conditions, and the added stress of emissions system demands.

1. Water Contamination — The #1 Killer

Water is the single most destructive contaminant for Tier 4 common rail injectors. At 23,000+ PSI operating pressure, even microscopic water droplets cause immediate damage:

- Water strips the thin lubrication film from injector internals, causing metal-to-metal contact

- Corrosion and pitting develop on precision surfaces that require micron-level smoothness

- Water disrupts fuel atomization, causing incomplete combustion and increased carbon deposits

- In freezing conditions, water in the fuel system can physically crack injector components

Where does water come from? Condensation in partially filled fuel tanks (extremely common on seasonal equipment), contaminated fuel from portable tanks or low-volume stations, damaged or missing fuel cap seals, and storage in humid environments.

2. Ultra-Low Sulfur Diesel (ULSD) and Reduced Lubricity

When the U.S. mandated ULSD in 2006, it removed up to 97% of diesel fuel’s sulfur content — and with it, much of the natural lubricity that protected injection system internals. Tier 4 common rail injectors are especially affected because their tight tolerances depend on fuel for internal lubrication.

Without consistent lubricity additive use, internal injector components wear faster — especially on equipment that operates intermittently or sits unused for weeks between jobs. The fuel literally isn’t slippery enough to protect the precision surfaces inside the injectors.

3. DPF Regeneration Stress

Diesel Particulate Filter regeneration is unique to Tier 4 engines and places additional stress on injectors that older Kubota systems never experienced. During active regeneration, the engine injects extra fuel late in the combustion cycle to raise exhaust temperatures high enough to burn off accumulated soot in the DPF.

This creates several problems for injectors over time:

- Increased duty cycles — injectors fire more events per cycle during regen

- Higher thermal stress — the additional late-cycle fuel raises temperatures around the injector tips

- Fuel wash risk — excess fuel can wash past piston rings and dilute engine oil, accelerating wear throughout the engine

- Carbon buildup on nozzle tips — incomplete combustion of the late-injection fuel deposits carbon on injector tips

Frequent or failed regeneration cycles are often an early indicator of injector degradation — the injectors can’t deliver fuel precisely enough for clean combustion, which loads the DPF faster, which triggers more regeneration, which stresses the injectors further. It’s a vicious cycle.

4. Short Run Times, Light Loads, and Excessive Idling

This is the operating condition that causes the most injector problems in Kubota equipment, and it’s also the most common. Many Kubota-powered machines — compact tractors, skid steers, generators, utility vehicles — spend significant time at idle, low RPM, or light loads.

Under these conditions:

- Combustion temperatures never reach optimal levels, leading to incomplete fuel burn

- Carbon deposits accumulate on injector nozzle tips because temperatures aren’t high enough to burn them off

- The DPF loads faster (more soot from incomplete combustion), triggering more frequent regeneration

- Fuel dilution of engine oil increases, reducing lubrication protection throughout the engine

A Kubota tractor that spends 4 hours a day moving dirt at moderate load will have far fewer injector problems than one that idles for 2 hours and does light mowing for 2 hours. The engines are designed for work — they suffer when they don’t get it.

Common Symptoms of Kubota Tier 4 Injector Problems

Injector problems typically develop gradually. Catching symptoms early — before they cascade into engine and emissions system damage — saves thousands in repairs.

- Hard starting or extended crank time — worn injectors can’t atomize fuel properly for cold starts. If your Kubota used to fire in 2 seconds and now takes 8–10, injectors are a likely culprit.

- Rough idle or engine surging — inconsistent fuel delivery from one or more degraded injectors causes uneven combustion across cylinders

- White or gray exhaust smoke — unburned fuel passing through the cylinders, especially at startup or under light load

- Black smoke under load — poor fuel atomization causes incomplete combustion. Nozzle tip carbon buildup or worn nozzle holes are the usual cause.

- Loss of power under load — the machine doesn’t dig, lift, or pull as hard as it used to. Often so gradual the operator doesn’t notice until performance is significantly degraded.

- Increased regeneration frequency — if the DPF is regenerating more often than normal, injectors that can’t burn fuel cleanly are usually the root cause

- Engine derate or limp mode — the ECU detects emissions-related faults and reduces power to protect the engine and aftertreatment system

- Fault codes — P0087/P0088 (fuel rail pressure), P0201–P0204 (injector circuit), P2146/P2149 (injector group), or platform-specific Kubota diagnostic codes related to fuel pressure, misfires, or emissions

For a deeper dive into warning signs across all diesel platforms: 7 Diesel Injector Failure Symptoms You Shouldn’t Ignore →

What Happens When Kubota Injector Problems Are Ignored

The cascade typically goes like this:

- Injector nozzle wear or carbon buildup → poor atomization → incomplete combustion

- Incomplete combustion → excess soot → DPF loads faster → more frequent regeneration

- Failed or incomplete regeneration → DPF becomes saturated → engine derate → potential DPF replacement ($2,000–$5,000)

- Fuel wash from worn injectors → fuel dilutes engine oil → accelerated wear on bearings, rings, and cylinder walls

- Severe over-fueling from stuck-open injector → cylinder wash → piston and ring damage → potential engine rebuild

We’ve seen Kubota owners turn a $1,500 injector set replacement into a $6,000–$10,000+ engine and emissions system repair by waiting too long. The math always favors early diagnosis.

How Much Do Kubota Tier 4 Injector Repairs Cost?

Understanding the cost range helps you make informed decisions about when to test, when to replace, and when prevention is cheaper than repair:

- Injector bench testing: $30–$75 per injector — the most cost-effective diagnostic step. Definitively tells you which injectors are good, which need cleaning, and which need replacement.

- Individual Tier 4 common rail injectors: $250–$600+ each depending on engine model

- Complete injector set (3 or 4 cylinder): $800–$2,500+ parts only

- Labor for injector replacement: $400–$1,000 depending on machine and accessibility (compact equipment can be tight to work on)

- DPF cleaning (if contaminated by bad injectors): $500–$1,500

- DPF replacement (if saturated beyond cleaning): $2,000–$5,000

- Engine repair from prolonged injector failure (fuel wash, ring damage): $5,000–$10,000+

How to Prevent Kubota Tier 4 Injector Failures

Most Tier 4 injector failures are preventable. These strategies address the root causes we see most often:

Manage Fuel Quality Aggressively

- Buy from high-volume, reputable fuel sources

- Don’t store fuel for more than 30 days without stabilizer

- Before seasonal startup, drain old fuel and refill fresh

- Keep fuel tanks as full as practical to minimize condensation airspace

Upgrade Filtration and Water Separation

- Factory filtration is adequate in clean, dry conditions — but most Kubota equipment operates in neither. An aftermarket secondary filter with water separation is cheap insurance.

- Drain the water separator regularly — weekly in humid conditions or daily when refueling from portable tanks in the field

- Replace filters every 200–500 hours, or sooner in dusty/wet environments

Use Lubricity Additives Consistently

- Treat every tank with a quality lubricity additive — not occasionally, every time

- This directly addresses the ULSD lubricity gap that accelerates Tier 4 injector wear

Operate Under Proper Load

- Minimize extended idling — shut down if idle exceeds 5 minutes

- Periodically run equipment at moderate to full load to reach operating temperature and burn off carbon deposits

- For standby generators: run at 50%+ load for 30 minutes monthly

Address Regeneration Issues Immediately

- Frequent or failed DPF regenerations are rarely a DPF problem — they’re usually an injector or combustion problem that’s loading the DPF faster than normal

- Don’t just force a manual regen and call it fixed. Diagnose the root cause — you’re treating the symptom, not the disease.

Test Injectors During Scheduled Downtime

- Pre-season bench testing catches failing injectors before they cause problems during your busy period

- Much cheaper to replace a marginal injector during planned downtime than to lose a machine mid-harvest or mid-project

For a complete preventative maintenance guide: 7 Kubota Injector Maintenance Tips →

Valley Fuel Injection: Your Kubota Injection Specialist

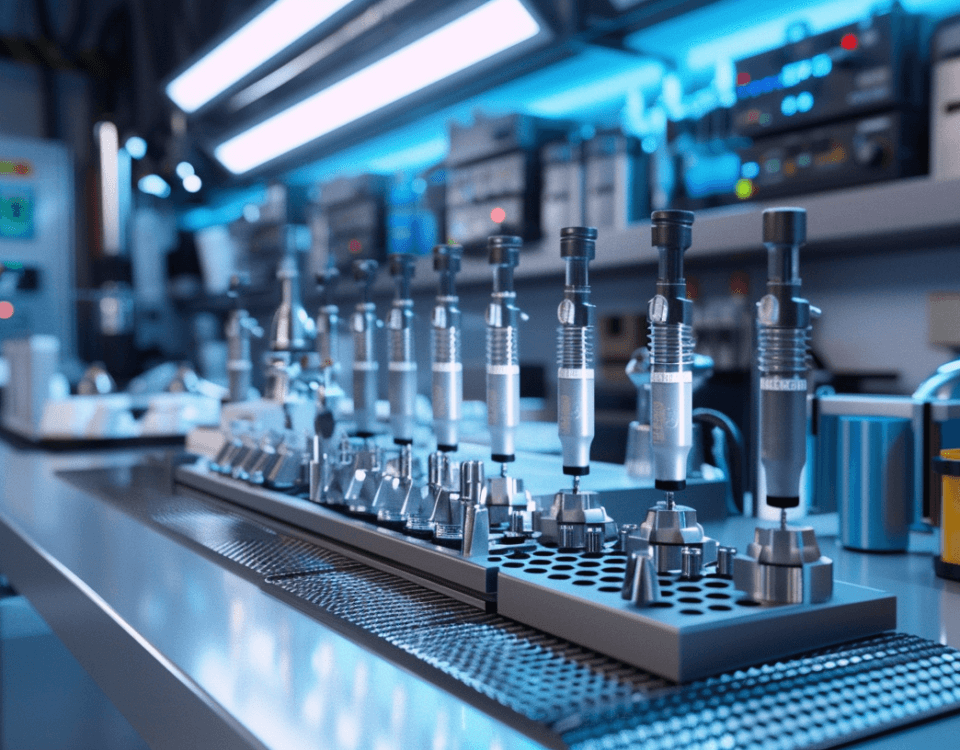

Valley Fuel Injection & Turbo is an authorized Kubota engine dealer and Bosch-certified diesel fuel injection center. We don’t just sell parts — we test, diagnose, and repair Kubota injection systems in-house on professional calibrated equipment.

- Kubota injector bench testing — flow rate, spray pattern, return volume, opening pressure tested to OEM specifications

- Injector cleaning and recalibration — ultrasonic cleaning and pressure adjustment for injectors that haven’t failed but need service

- Genuine Kubota and Bosch-remanufactured injector sales — matched to your specific engine model and serial number

- Injection pump diagnosis — rail pressure testing and pump evaluation

- Mail-in service — pull your injectors and ship them to us from anywhere. Results in 1–2 business days.

We serve agricultural operations, construction companies, rental fleets, and equipment owners from Sacramento, Davis, Woodland, Yuba City, Stockton, Vacaville, Chico, Redding, Reno, and across Northern California and Nevada.

Kubota running rough? Hard starts? Smoke? Frequent regens?

Don’t wait for a $1,500 injector problem to become a $10,000 engine repair. Call us for Kubota injector testing, diagnosis, and repair — or ship your injectors for mail-in bench testing.

Call (530) 668-0818 or contact us online

Valley Fuel Injection & Turbo, Inc.

1243 E Beamer St, Suite C, Woodland, CA 95776

Monday–Friday, 7:00 AM – 4:30 PM PST

Related reading: 7 Kubota Injector Maintenance Tips · Diesel Injector Failure Symptoms · CP4 Pump Failures · How Injectors Are Tested · Diesel Engine Maintenance Services · Yanmar Engine Parts & Service