Why Your Diesel Engine Cranks But Won’t Start — 7 Common Causes (And How to Fix Them Fast)

11/12/2025

Kubota Injector Problems in Tier 4 Engines: Causes, Symptoms, Costs, and Prevention

01/14/2026Published by Valley Fuel Injection & Turbo, Inc. | Woodland, CA

Reviewed by VFI’s Bosch-Certified Diesel Technicians

Modern diesel engines deliver impressive power, efficiency, and emissions compliance. But one component has become infamous for sudden and catastrophically expensive failures: the Bosch CP4 high-pressure fuel injection pump.

Originally engineered around European diesel fuel standards, the CP4 has proven far less forgiving under North American operating conditions. When it fails, it doesn’t just stop pumping fuel — it sheds metal shavings that contaminate the entire fuel system, turning a single component failure into a $8,000–$12,000+ repair bill.

At Valley Fuel Injection & Turbo, we see the aftermath of CP4 failures regularly — contaminated injectors, destroyed fuel rails, and tanks full of metal debris. This guide explains why CP4 pumps fail, how to recognize warning signs early, what a complete failure costs, and the preventative steps that can save you thousands.

What Is a CP4 Injection Pump?

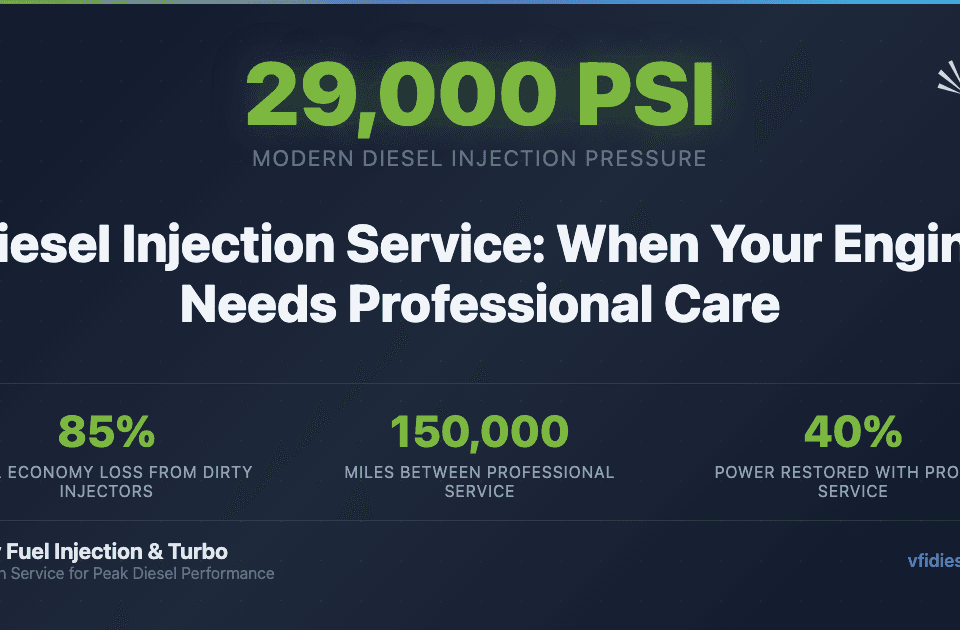

The CP4 is a high-pressure common rail fuel injection pump manufactured by Bosch. It pressurizes diesel fuel to 29,000+ PSI and delivers it to the common fuel rail, where electronically controlled injectors fire it into each cylinder with precision timing.

Compared to its predecessor — the Bosch CP3 — the CP4 operates with tighter internal tolerances and a thinner lubrication margin. While this improves efficiency and emissions performance, it also makes the pump extremely sensitive to fuel quality, water contamination, and air intrusion.

Which Vehicles Use the CP4 Pump?

- Ford 6.7L Powerstroke (2011–present) — the most common CP4 failure platform in our shop

- GM 6.6L Duramax LML/L5P (2011–present)

- Ram 6.7L Cummins (some 2019+ applications)

- Jeep 3.0L EcoDiesel

- Various European diesel platforms (BMW, VW/Audi TDI)

If your truck was built after 2010 and runs a diesel, there’s a good chance it has a CP4. The earlier CP3-equipped trucks (like the 2007.5–2018 6.7 Cummins and pre-2011 Duramax) use a fundamentally more durable pump design.

Why CP4 Injection Pumps Fail

CP4 failures aren’t random. They result from a combination of design limitations and real-world fuel conditions that the pump wasn’t built to handle.

1. Ultra-Low Sulfur Diesel (ULSD) and Reduced Lubricity

When the U.S. mandated Ultra-Low Sulfur Diesel in 2006, it removed up to 97% of the sulfur content — and with it, much of the fuel’s natural lubricating properties. The CP4’s internal cam and roller assemblies rely on fuel for lubrication (not engine oil like the 6.0 Powerstroke’s HEUI system). Running on marginally lubricated fuel accelerates internal wear from day one.

2. Extremely Tight Internal Tolerances

The CP4’s precision is also its weakness. Microscopic debris that wouldn’t affect a CP3 can score internal surfaces in a CP4, creating metal-on-metal wear that escalates rapidly. Factory fuel filtration systems often aren’t fine enough to fully protect the pump in real-world conditions.

3. Water Contamination

Even small amounts of water in the fuel strip what little lubrication exists, promote corrosion on internal surfaces, and cause metal-to-metal contact. This is especially problematic for trucks that refuel from inconsistent sources, sit for extended periods, or operate in humid climates.

4. The Catastrophic Failure Mode

This is why you can’t just replace the pump. By the time you know it’s failed, the damage has already spread system-wide.

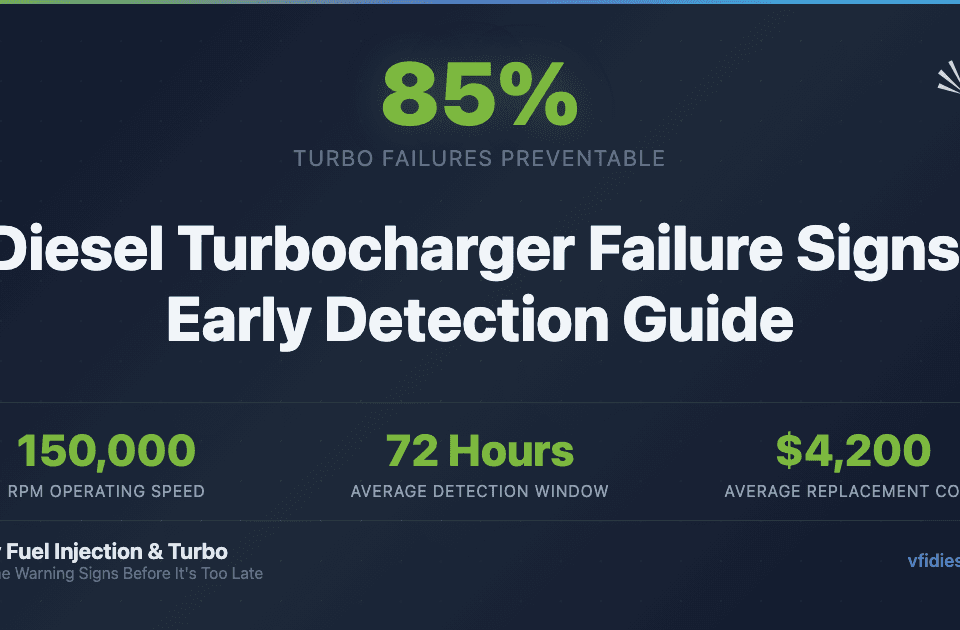

Early Warning Signs of CP4 Failure

Catching a CP4 problem early — before catastrophic metal contamination — can save you thousands. Watch for these symptoms:

- Hard starting or extended crank times — the pump can’t build sufficient rail pressure

- Sudden loss of power under load — especially noticeable while towing or accelerating

- Rough idle, misfires, or surging — inconsistent fuel pressure causes erratic engine behavior

- Fuel pressure fault codes — P0087 (fuel rail pressure too low), P0088 (too high), or platform-specific pressure codes

- Metal flakes or “glitter” in the fuel filter — this is the red flag. If you find metal during a fuel filter change, stop driving immediately

What Happens When a CP4 Fails Completely

When a CP4 fails catastrophically, metal debris is circulated throughout the entire fuel system. The damage typically includes:

- Contaminated fuel rails — metal particles embed in rail surfaces and cannot be cleaned

- Damaged or seized injectors — metal debris scores internal injector components, requiring full replacement of all injectors

- Contaminated fuel lines and return circuits — every line that carries fuel is now carrying metal

- Fuel tank contamination — the tank often needs to be removed, professionally cleaned, or replaced entirely

Because modern common rail fuel system components are built to micron-level tolerances, they cannot be reliably cleaned once metal contamination occurs. Flushing isn’t enough — the metal particles embed in surfaces and continue causing damage even after cleaning attempts.

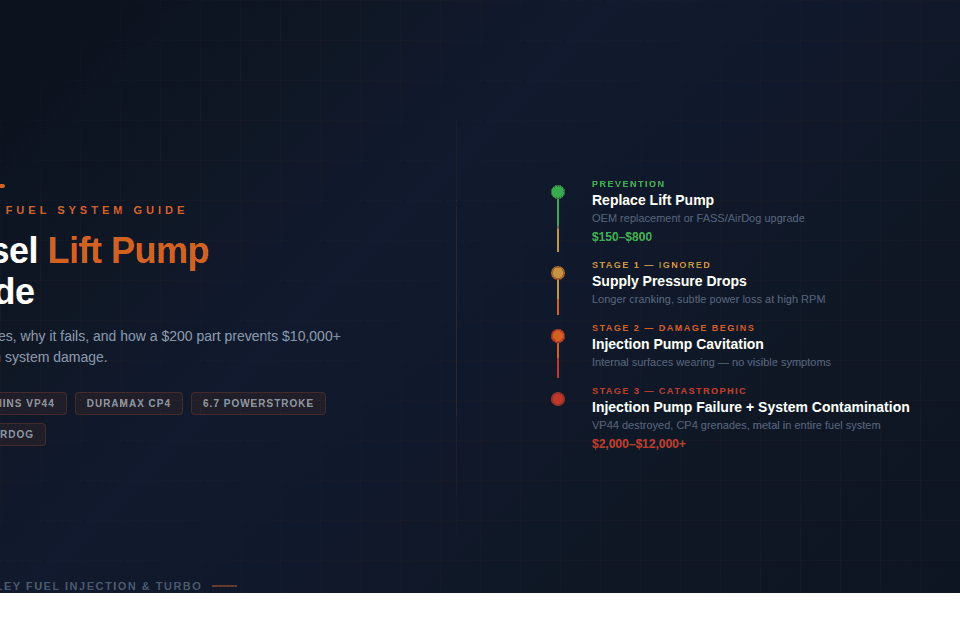

How Much Does a CP4 Failure Cost to Repair?

This is the question everyone asks, and the answer is painful:

- CP4 pump replacement only (caught early before contamination spreads): $2,000–$3,500

- Pump + injectors + rails (moderate contamination): $6,000–$9,000

- Full fuel system replacement (catastrophic failure — pump, all injectors, rails, lines, tank cleaning): $8,000–$12,000+

- CP3 conversion (preventative, before failure): $2,500–$4,000

The math is clear: a $2,500–$4,000 preventative CP3 conversion costs a fraction of the $8,000–$12,000+ catastrophic failure repair. For trucks that tow heavy, have high mileage, or are used commercially, the conversion pays for itself the moment you avoid a single CP4 failure.

CP4 vs. CP3: Why the Older Design Survives

The Bosch CP3 pump — used in 2003–2010 Cummins and pre-2011 Duramax trucks — has earned a reputation as one of the most reliable high-pressure diesel pumps ever made. Here’s why:

- Larger internal lubrication margins — more tolerant of ULSD’s reduced lubricity

- Greater contamination tolerance — less likely to catastrophically fail from minor debris

- Graceful failure mode — when a CP3 does eventually wear, it typically loses pressure gradually rather than shedding metal

- Proven longevity — CP3 pumps regularly exceed 300,000 miles with basic maintenance

This is why the CP3 conversion has become the most popular preventative modification for CP4-equipped trucks. The conversion replaces the CP4 with a CP3 and the necessary adapters to make it work on the newer platform. It’s a proven solution that eliminates the catastrophic failure risk entirely.

How to Reduce the Risk of CP4 Failure

If you’re keeping your CP4 (or aren’t ready for a conversion yet), these steps significantly reduce failure risk:

Upgrade Fuel Filtration

Install an aftermarket fuel filtration system with water separation that exceeds factory spec. This is the single most impactful protection you can add. Look for systems that filter to 2 microns — factory filters are typically 5–7 microns.

Use Quality Fuel Additives

A lubricity additive restores what ULSD removed. Use it consistently — not just occasionally. Stanadyne Performance Formula and Hot Shot’s Secret Diesel Extreme are popular choices with proven results.

Inspect Fuel Filters Religiously

Every fuel filter change is a free diagnostic opportunity. Cut the old filter open and inspect it. Wipe the housing with a white cloth. Any metallic debris means internal pump wear has started — act immediately.

Address Symptoms Immediately

Hard starts, power loss, surging, or fuel pressure codes are not “wait and see” situations on a CP4 truck. Every mile driven after symptoms appear risks turning a pump-only replacement into a full system rebuild.

Consider Preventative Conversion

For trucks that tow heavy, are used commercially, or have exceeded 100,000 miles, a CP3 conversion eliminates the risk entirely and is the most cost-effective long-term strategy.

Why Choose Valley Fuel Injection for CP4 Diagnosis and Repair?

CP4 failures require specialized diagnosis and precision fuel system work. At Valley Fuel Injection, our Bosch-certified facility in Woodland, CA has the calibrated test equipment and expertise to:

- Diagnose early-stage CP4 wear before catastrophic failure

- Test and replace contaminated injectors on our Bosch-certified bench

- Perform complete fuel system decontamination when full failure has occurred

- Install CP3 conversions for preventative protection

We serve diesel truck owners from Sacramento, Roseville, Stockton, Vacaville, Reno, and across Northern California and Nevada. We also offer mail-in injector testing — if your shop suspects CP4 contamination, send us the injectors and we’ll test them on our bench and report exactly what’s needed.

Suspect CP4 problems? Don’t keep driving.

Every mile on a failing CP4 risks turning a $3,000 pump replacement into a $12,000 fuel system rebuild. Call us for diagnosis and repair options — including CP3 conversion.

Call (530) 668-0818 or contact us online

Valley Fuel Injection & Turbo, Inc.

1243 E Beamer St, Suite C, Woodland, CA 95776

Monday–Friday, 7:00 AM – 4:30 PM PST

Related reading: VP44 Injection Pump Failure Guide · 6.0 Powerstroke Injector Problems · Diesel Injector Failure Symptoms · 6.7 Cummins Injector Problems · How Injectors Are Tested · VP44 vs. Common Rail Systems