7 Essential Maintenance Tips for Diesel Fuel Injectors in Kubota Equipment

11/11/2025

CP4 Injection Pump Failures: Symptoms, Causes, Repair Costs, Prevention

01/14/2026Published by Valley Fuel Injection & Turbo, Inc. | Woodland, CA

Reviewed by VFI’s Bosch-Certified Diesel Technicians

You turn the key. The engine cranks strong — starter sounds healthy, battery is fine — but the engine refuses to fire. No combustion, no rumble. Just cranking.

This is one of the most common and frustrating diesel problems, and it hits everything from pickup trucks to tractors to generators. The good news: a diesel that cranks but won’t start is almost always a fuel delivery, air intrusion, or combustion support problem — not a catastrophic engine failure. In most cases, the fix is something you or your shop can identify without tearing the engine apart.

At Valley Fuel Injection & Turbo, we diagnose diesel no-start problems every week. This guide walks through the 7 most common causes in order of likelihood, how to diagnose each one, what it costs to fix, and when the problem points to something more serious like failing injectors or a failed injection pump.

- Listen — Do you hear the lift/fuel pump prime when you turn the key to ON (before cranking)? A humming sound for 1-2 seconds means the pump is working.

- Look — Check the dash for warning lights: glow plug indicator, water-in-fuel light, low fuel pressure warning, check engine light.

- Smell — Do you smell raw diesel at the exhaust while cranking? If yes, fuel is reaching the cylinders but not igniting (glow plug or compression issue). If no smell, fuel isn’t getting there (fuel delivery issue).

- Scan — If you have an OBD-II scanner, pull codes before doing anything else. A single code can save hours of guessing.

Cause #1: Fuel Starvation — Empty Tank, Bad Fuel, or Water Contamination

This is the most common cause of a diesel no-start, and it’s the easiest to overlook. Diesel engines are completely dependent on a continuous supply of clean fuel at adequate pressure. Any interruption — even momentary — and the engine won’t fire.

Why it happens:

- Tank ran dry (or near-dry) and air entered the fuel system

- Water accumulated in the tank from condensation or bad fuel

- Fuel sat too long and degraded (common in seasonal equipment like generators, tractors, and construction machinery)

- Bad batch of fuel from a station with contaminated storage tanks

Symptoms: Engine cranks normally with good speed, no smoke from the exhaust (because no fuel is reaching the cylinders), fuel gauge may read incorrectly on older equipment.

How to fix:

- Refill with fresh, clean diesel from a reputable station

- Drain the water separator — most diesels have one near the primary fuel filter. Open the petcock valve and drain until clear fuel flows

- Bleed the fuel system to purge trapped air (see Cause #4 below)

- On Kubota and Yanmar equipment that sits seasonally, stale fuel is the #1 no-start cause

Cause #2: Clogged Fuel Filter

The fuel filter is the gatekeeper between your tank and your injection system. When it clogs, fuel pressure drops below the minimum threshold needed for the injection pump to build pressure and fire the injectors. The engine cranks but starves.

Why it happens:

- Normal contamination accumulation over time (dirt, rust, tank debris)

- Algae/microbial growth in the fuel — especially in warm climates or after fuel sits for months

- Paraffin wax gelling in cold weather (diesel fuel gels when temperatures drop below its cloud point)

- Water that bypassed the separator and saturated the filter media

Symptoms: Engine cranks, may sputter or fire briefly then die. Often worse after the vehicle or equipment has been sitting. May start fine when warm but not when cold (wax buildup melts when warm).

How to fix:

- Replace both primary and secondary fuel filters — never just one. A clean secondary filter with a clogged primary doesn’t help.

- Prime the system with the lift pump or manual priming lever after filter replacement

- In cold weather no-starts, try a fuel filter with an integrated heater or use a winter-blend diesel with anti-gel additive

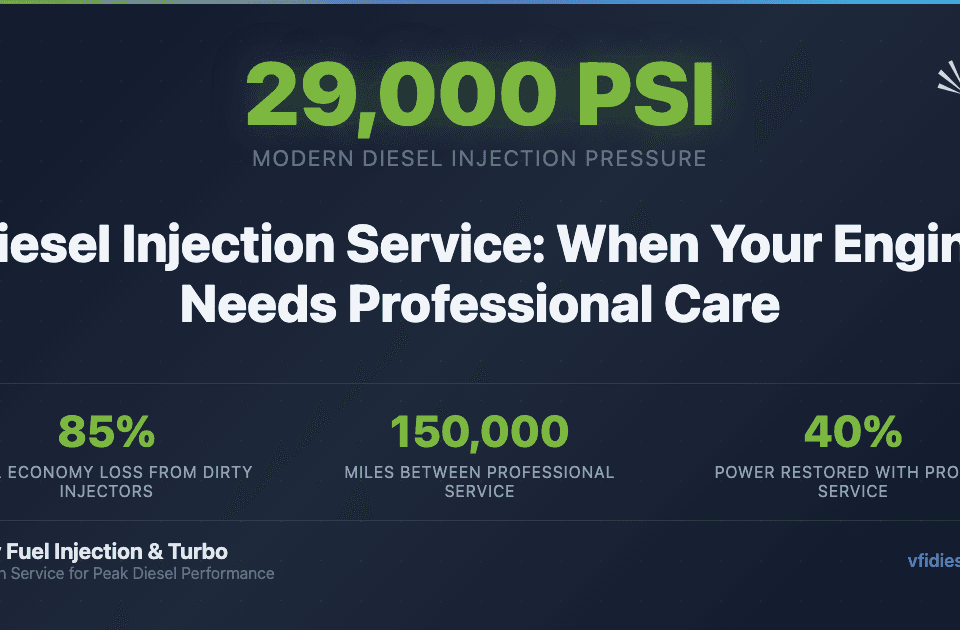

A restricted filter can drop fuel pressure by 50+ PSI — more than enough to prevent starting. On modern common rail systems that operate at 23,000–29,000+ PSI, the high-pressure pump depends on adequate supply pressure from the lift pump through clean filters. Starve the supply and the whole system fails.

Cause #3: Failed Glow Plugs or Glow Plug System

Unlike gasoline engines that use spark plugs, diesels rely on compression heat to ignite fuel. In cold conditions, the compressed air may not get hot enough on its own — that’s where glow plugs come in. They pre-heat the combustion chamber so the fuel ignites on the first compression stroke.

When glow plugs fail, the engine doesn’t have enough heat to ignite the fuel, especially in temperatures below 40°F (4°C).

Symptoms:

- Hard or no start in cold weather, but starts fine when warm

- Excessive white smoke during cranking (fuel is entering the cylinder but not igniting fully)

- Glow plug dash light stays on longer than normal, flashes, or doesn’t illuminate at all

- Engine eventually starts after extended cranking (combustion heat from cranking eventually warms things enough)

How to diagnose:

- Multimeter test: A good glow plug reads 0.5–2 ohms resistance. Open circuit (infinite resistance) = dead plug.

- Check the glow plug relay/controller: Listen for the relay click when key is turned to ON. If no click, the relay may have failed — no power reaches the plugs regardless of their condition.

- Check voltage at the plug connector: You should see battery voltage (12V) when the glow plug cycle is active. No voltage = wiring or relay problem.

How to fix: Replace all glow plugs at once — if one has failed, the others are nearing end of life. Mismatched old and new plugs create uneven heating across cylinders. Also check the relay/controller, as it’s a common failure point that gets overlooked.

Cost: Glow plugs typically run $15–$40 each, plus labor. A relay is usually $50–$150. Total repair: $150–$500 depending on the platform and how accessible the plugs are.

Cause #4: Air in the Fuel System (Air Lock)

Diesel fuel systems are designed to be completely sealed and air-free. When air enters the system, it creates pockets that prevent fuel from flowing to the injection pump or injectors. The engine cranks but has nothing to burn.

Why it happens:

- Running the tank empty (the most common cause)

- Fuel filter change without proper priming afterward

- Loose fuel line fittings or cracked rubber lines (especially on older equipment)

- Failed lift pump seal allowing air to enter the suction side

- Injector return line leak

Symptoms: Engine cranks, may fire briefly and stall, then refuses to restart. If you have a clear return line, you’ll see air bubbles. The engine may start after extended cranking (as air gradually works through the system) but runs rough until all air is purged.

How to fix:

- Manual bleeding: Crack the bleed screw on top of the fuel filter housing (most diesels have one). Operate the manual priming lever or turn the key to ON to activate the electric lift pump. Pump until bubble-free fuel flows, then tighten the bleed screw.

- Injector line bleeding: If the filter bleed doesn’t work, crack the injector line fittings at the injectors (use rags — fuel will spray). Crank the engine until fuel appears at each fitting, then tighten. Start with the injector closest to the pump.

- Check for the source: Once running, inspect all fuel lines, fittings, and the lift pump for the entry point. Air locks don’t happen without a cause — find and fix the leak or you’ll be bleeding the system again.

Air locks are especially common on Bosch VE-pump systems and older mechanical diesels. On modern common rail systems, even small air intrusions can prevent the high-pressure pump from building rail pressure.

Cause #5: Failed Lift Pump (Transfer Pump)

The lift pump (also called transfer pump or supply pump) moves fuel from the tank to the high-pressure injection pump. If it fails, the injection pump has nothing to pressurize and the injectors have nothing to deliver.

Why it happens:

- Electric lift pump motor burns out (wear, age, debris in tank)

- Mechanical lift pump diaphragm tears (on older engines)

- Wiring/relay failure cuts power to the pump

- Pickup tube in tank is clogged or damaged

Symptoms: No priming hum when you turn the key to ON. Low or zero fuel pressure at the injection pump inlet (should be 5–17 PSI depending on application). Engine cranks with no smoke whatsoever.

How to diagnose:

- Listen test: Turn key to ON (don’t crank). Put your ear near the fuel tank or fuel lines. You should hear a brief humming/buzzing sound. No sound = pump not running.

- Pressure test: Install an inline fuel pressure gauge at the injection pump inlet. Crank the engine. If pressure is below spec, the lift pump is the problem.

- Check power: Before replacing the pump, verify the pump is getting power — test voltage at the pump connector. A blown fuse or bad relay is a $5 fix vs. a $200+ pump.

Cost: Aftermarket electric lift pump: $150–$400 depending on application. OEM: $200–$600. Labor is usually minimal since the pump is externally accessible on most platforms.

Cause #6: Faulty Injectors or Injection Pump

When fuel delivery and air supply are confirmed good but the engine still won’t start, the problem may be with the components that actually deliver fuel to the cylinders — the injectors or the high-pressure injection pump itself.

Injector Problems

Worn, clogged, or leaking injectors can’t atomize fuel properly. Instead of a fine mist that ignites on compression, you get a stream or drip that won’t combust. Common across all platforms but particularly prevalent on high-mileage trucks.

Symptoms of injector-related no-start:

- Cranks with no smoke (injectors aren’t delivering any fuel) or black/white smoke (poor spray pattern, fuel entering but not burning properly)

- Excessive fuel return volume — crack the return lines and if fuel is pouring back rather than a small trickle, injectors have internal leakage

- Engine fires on one or two cylinders but won’t fully catch

The definitive test is bench testing on calibrated equipment. At Valley Fuel Injection, we test injectors on our Bosch-certified test bench measuring spray pattern, flow rate, return volume, and electrical response. This tells you exactly which injectors have failed — no guessing. Watch how we test injectors →

Injection Pump Failure

If the high-pressure pump can’t build sufficient pressure, the injectors can’t fire regardless of their condition.

- VP44 (5.9 Cummins): PSG electronics failure causes intermittent or complete no-start. Often heat-related — fails when hot, starts when cool. P0216 timing code is the classic indicator.

- CP4 (6.7 Powerstroke, Duramax LML/L5P): Internal failure sheds metal into the entire fuel system. Check fuel filter for metallic debris.

- CP3 (6.7 Cummins, older Duramax): Generally very reliable but can wear at high mileage. Typically loses pressure gradually rather than sudden failure.

Cost: Injector bench testing: $30–$75 per injector. Remanufactured injector sets: $1,200–$4,500 depending on platform. Injection pump replacement: $1,500–$5,000+ depending on type. Shop remanufactured injectors →

Cause #7: Sensor or ECU Failure

Modern diesel engines rely on electronic sensors to tell the ECM when and how to fire the injectors. If a critical sensor fails, the ECM may not command injection at all — the engine cranks perfectly but no fuel is delivered because the computer doesn’t know where the engine is in its rotation.

The two sensors that cause the most no-starts:

- Crankshaft Position Sensor (CKP): Tells the ECM the engine’s rotational position and speed. If it fails, the ECM doesn’t know when to fire injectors. This is a $20–$50 part that causes symptoms identical to a failed injection pump — always test or replace this before spending $1,500+ on a pump. Common codes: P0335, P0336.

- Camshaft Position Sensor (CMP): Works with the CKP to determine cylinder position for injection timing. Failure can cause no-start or extreme rough running. Common codes: P0340, P0341.

Other sensors that can cause no-start:

- Fuel Rail Pressure Sensor: If it reads incorrectly, the ECM may limit fueling or shut down injection entirely

- ICP Sensor (6.0/7.3 Powerstroke): Injection Control Pressure sensor — if it reads low or fails, the PCM won’t enable injectors

- FICM (6.0 Powerstroke): The Fuel Injection Control Module must deliver 48V to fire HEUI injectors. Low voltage = no start. Check FICM voltage before replacing injectors.

How to diagnose:

- Scan for codes first — sensor failures almost always set a diagnostic trouble code. A $30 code reader can save you hours of guessing.

- Check for injector pulse: Use a noid light on an injector connector while cranking. No pulse = ECM isn’t commanding injection (sensor, wiring, or ECM problem). Pulse present = injectors are being commanded but may not be responding (injector or fuel supply problem).

- Test sensor resistance and wiring: CKP and CMP sensors typically read 500–1,500 ohms. Check wiring for chafing, corrosion, or loose connectors.

Diesel No-Start Diagnosis by Platform

Different engines have different common failure points. Here’s where to look first based on your platform:

- 5.9 Cummins (VP44, 1998.5–2002): Lift pump → CKP sensor → VP44 pump. In that order. Don’t touch the VP44 until you’ve ruled out the other two.

- 6.7 Cummins (2007.5+): Fuel filter → Lift pump → Injector balance rates → CP3 pump wear

- LB7 Duramax (2001–2004): Injector failure → Fuel filter → Glow plugs in cold weather

- LLY/LBZ/LMM Duramax (2004–2010): Fuel filter → Lift pump → Injectors at higher mileage

- 6.0 Powerstroke (2003–2007): FICM voltage → ICP/IPR → Glow plugs → HPOP → Injectors (stiction). This engine has the most overlapping failure points.

- 7.3 Powerstroke (1994–2003): CPS → Glow plug relay → ICP sensor → Fuel bowl/filter

- Kubota / Yanmar Equipment: Stale fuel → Air lock → Glow plugs → Injector nozzle carbon buildup

When to Call a Professional

Most of the causes above (fuel, filters, glow plugs, air bleeding, sensors) are DIY-friendly or straightforward for a general mechanic. But if you’ve worked through the list and the engine still won’t start, or if you’ve identified injector or pump problems, that’s when specialized diesel fuel injection expertise matters.

Valley Fuel Injection & Turbo in Woodland, CA specializes in exactly this — the fuel system problems that general shops struggle to diagnose:

- Injector bench testing on Bosch-certified equipment — definitive answers, not guesswork

- Injection pump diagnosis and rebuilding — VP44, CP3, CP4, and more

- Complete fuel system decontamination after CP4 failures

- Mail-in testing available — pull the injectors, ship them to us, get results in 1–2 business days

We serve diesel owners from Sacramento, Roseville, Davis, Stockton, Vacaville, Reno, and across Northern California and Nevada.

Diesel cranks but won’t start?

If you’ve worked through the basics and suspect injectors, an injection pump, or a fuel system problem you can’t pin down — we can help. Bosch-certified diagnosis, professional bench testing, and expert repair.

Call (530) 668-0818 or contact us online

Valley Fuel Injection & Turbo, Inc.

1243 E Beamer St, Suite C, Woodland, CA 95776

Monday–Friday, 7:00 AM – 4:30 PM PST

Related reading: 7 Diesel Injector Failure Symptoms · VP44 Injection Pump Failure Guide · CP4 Pump Failure: Causes & Costs · 6.0 Powerstroke Injector Problems · LB7 Duramax Injector Replacement · 6.7 Cummins Injector Problems · How Injectors Are Tested